In the world of metal building construction, estimating is a critical component of any successful project. At MBCI, we recognize the importance of providing accurate, timely, and professional estimates with comprehensive bids so that you know your exact cost and have the information you need to win the project. Our streamlined estimating process is designed to deliver precise quotes efficiently, helping to ensure your project’s success from the start.

Clarity Is Key: Providing Complete Project Details

Providing complete and detailed information is essential to receive the most efficient estimate for your project. Here are some key elements to include:

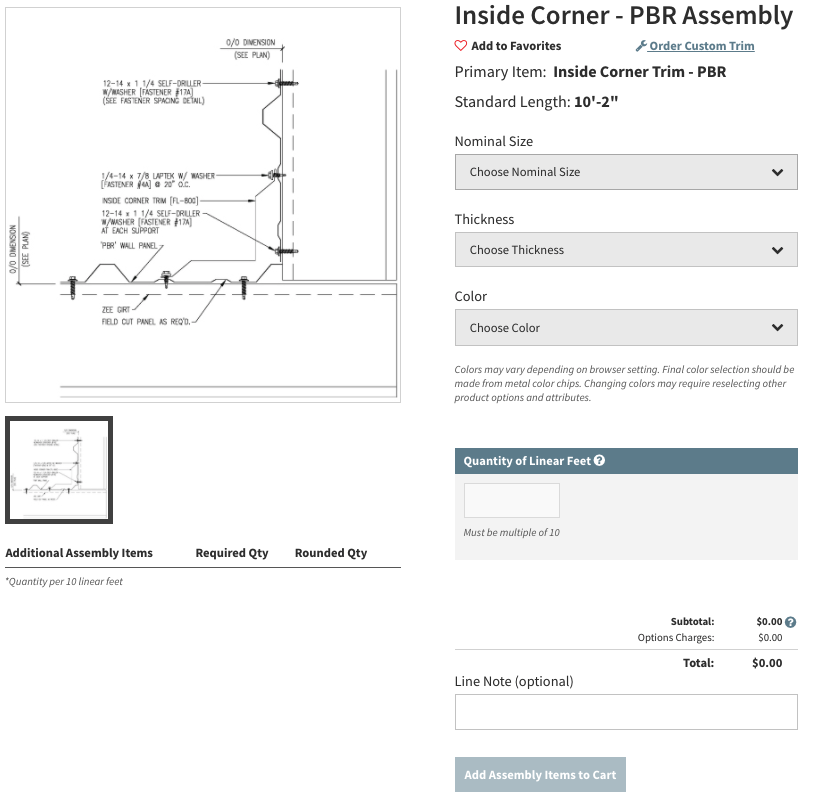

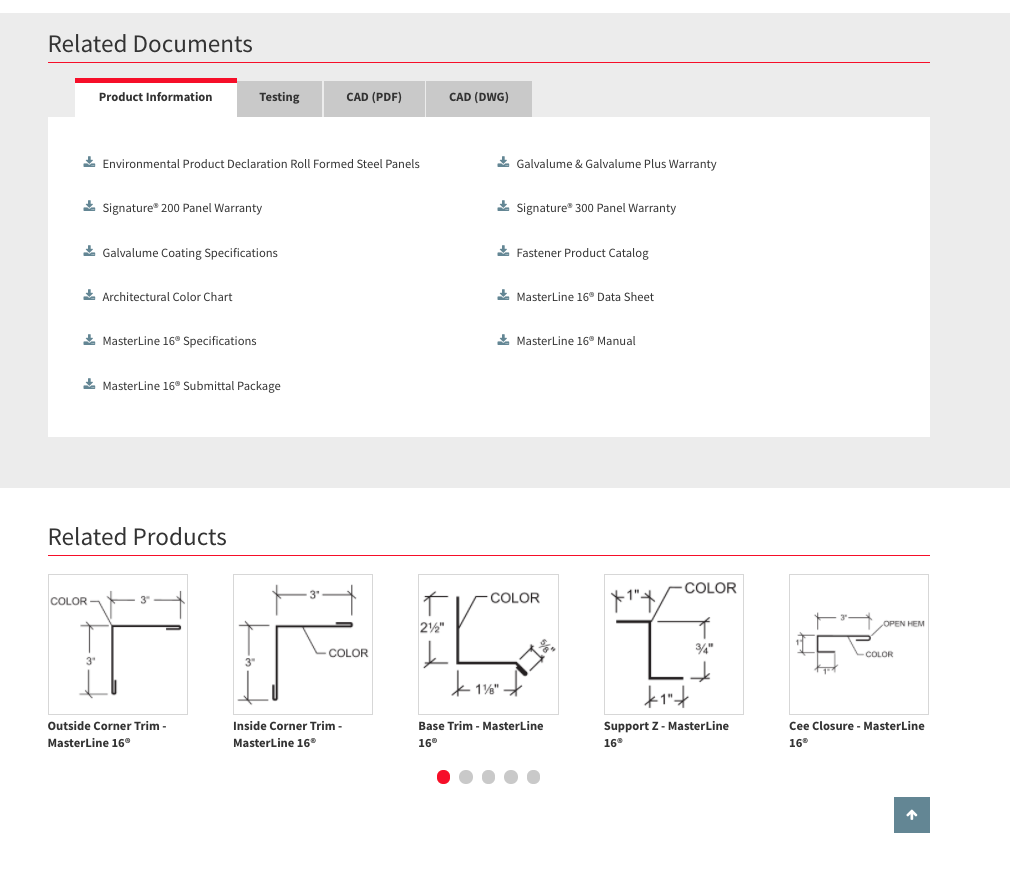

- Detailed architectural drawings: These are crucial for understanding the scope and specifics of your project. They provide a visual representation that helps in planning and executing the construction process accurately.

- Specify all desired products: Whether it’s roofing, walls, soffit, or fascia, be clear about what you need. This specificity helps avoid confusion and ensures that the right materials are used.

- Indicate different product types: Clearly mark different product types for various building sections. This helps organize the construction process and ensures that each section is constructed with the appropriate materials.

- Multiple buildings: If your project includes multiple buildings, be sure to document this information, as it impacts overall planning and resource allocation.

- Special requirements or deadlines: Let us know of any unique needs or time constraints up front so we can tailor our services to meet your project needs.

What Our Estimating Team Delivers

Our estimating team is committed to providing comprehensive and detailed estimates, including:

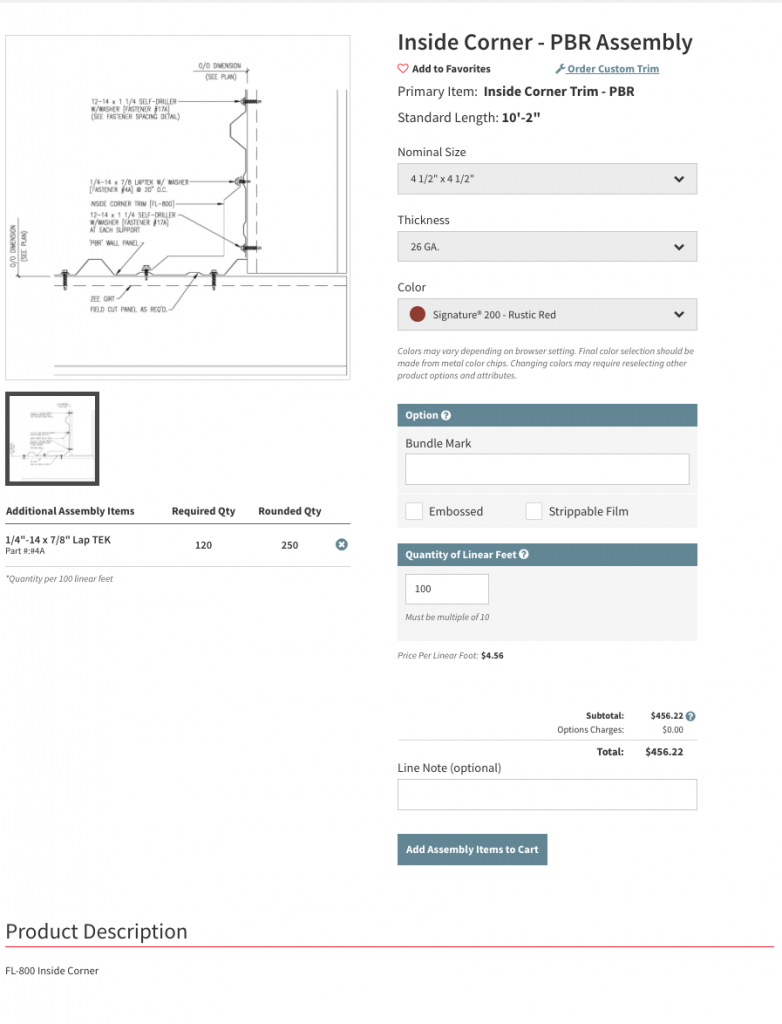

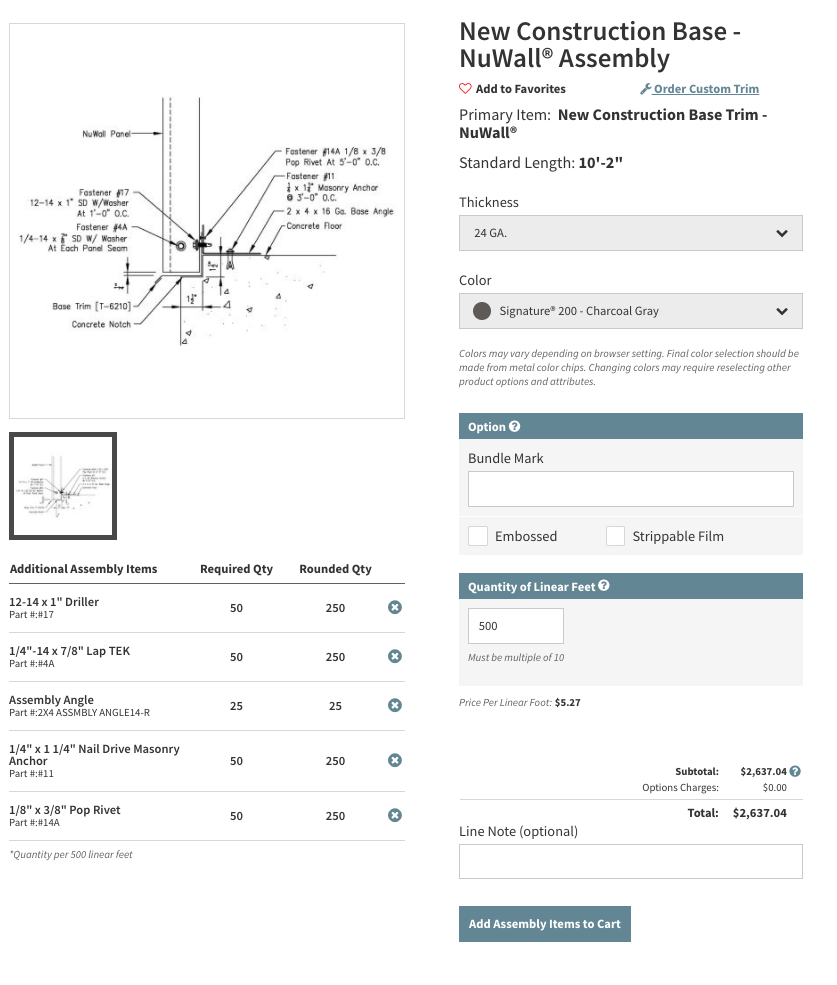

- Detailed product cost breakdowns: We provide a breakdown of costs for each product, helping you manage your budget effectively.

- Color-coded architectural drawings: Visualize product placement easily. Our architectural drawings can help you understand where each product will be used, making the construction process smoother.

- Accurate square footage and linear footage calculations: Ensure precise measurements for your project. Accurate calculations are crucial for ordering the right amount of materials and avoiding waste.

- Complete material lists: We offer everything from major components to fasteners. This comprehensive list ensures that you have everything you need for your project.

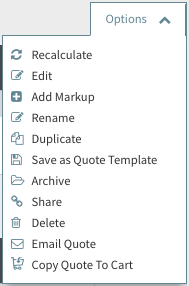

- Quick turnaround times: Our dedicated team’s efficient process ensures you get a complete bid based on your requested bid date.

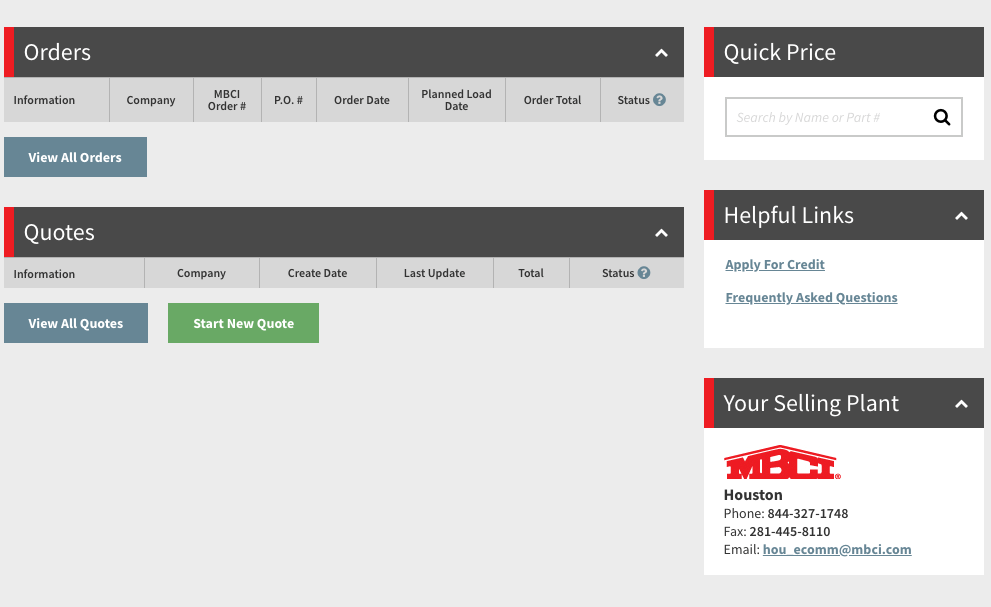

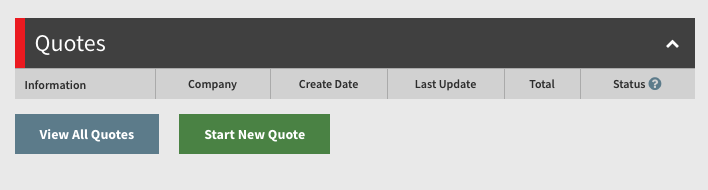

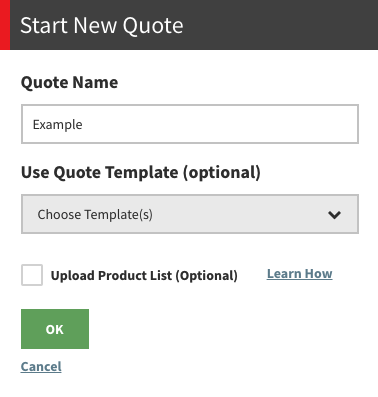

Tools for Success

To facilitate a smooth estimating process, ensure you have the following:

- Architectural drawings: Essential for accurate planning.

- Clear Scope of Work: Define what needs to be done.

- Project timeline/deadlines: Keep your project on schedule.

- Product preferences: Specify any particular brands or types.

- Special pricing requirements: If applicable, let us know about any pricing considerations.

Why Details Matter

The more complete the information we receive upfront, the faster we can process your estimate without interruptions or delays. This attention to detail helps us maintain our commitment to quick turnaround times and ensures you receive the accurate quote you need.

Our dedicated estimating team works closely with project coordinators and sales managers to address every detail. We understand the pressure of tight deadlines, and our streamlined process is designed to help you meet those challenges head-on.

Ready to get started? Contact your Project Coordinator today with your project details. We’re here to help make your next metal building project a success.