Panel Repair Technical Bulletin

There’s no getting around it. Erecting any building involves thousands of parts. Different sizes, colors, lengths, types – you name it. Depending on the nature of the project, there could be numerous parts to be ordered and accounted for. Although MBCI simplifies the process, it can still be a lot to manage. Until now, everyone has come up with their own method – like the many long-timers who write it all out by hand. But for those newer to the process, it can be overwhelming. Now we’re taking the guesswork out of it and making the process considerably easier, with exciting new user-friendly features on our online ordering platform.

With the new addition of “Assemblies”, you can simply choose which area of a building you’re working on, fill in some details such as panel type, trim condition, attachment type, size, and color, and the system will do the rest of the work for you – making sure you have any necessary fasteners, accessories or other parts, adding everything to your order. No longer will you have to study construction drawings, note fastener types and add everything to your order by hand. No longer will you find yourself on-site without the needed materials. And, even if you do, the online ordering platform is available right from your phone to get whatever you need on the way ASAP.

As Director of Development Tyler Roose says, “We’ve heard testimonials from many, many customers and it’s the only way they like to order anymore. It’s a huge time saver.”

Ready to get started? Head to shop.mbci.com. If you are registered and an existing customer, you should have everything you need to log in. For new customers, simply fill in the requested information and provide your customer number to create an account. If you don’t have a customer number, reach out to your district sales manager or customer service rep.

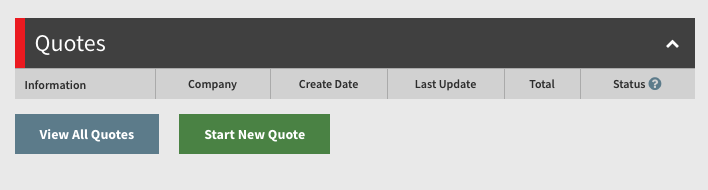

Once you’re logged in, you’ll see the dashboard, which has links to any existing orders, quotes or other information you may need.

To get started on a new quote, simply click the “Start New Quote” button, which will give you an option to name your new quote and use a template if desired (more on that later).

Once you’ve begun a new quote, you will land on the Products page, where you have the option to shop by category, such as accessories, fasteners, panels, structural and trim. However, for this purpose, let’s focus on the newest option: Assemblies.

Choosing “Assemblies” will open a list of component types to choose from. For this example, we’re selecting PBR, but you’ll choose whichever is appropriate to your project. From the next list, select the area you’re working on, such as eaves, gutters, valleys, corners, bases, etc.

Once you’ve selected your assembly, the form will prompt you to choose details such as thickness, color, lineal footage of the assembly being used, and further options depending on the assembly and area you’re working on. Then, all the core trim items as well as necessary fasteners, sealants and accessories are automatically added to your material list for review. Notice the additional parts automatically added on the PBR form. If satisfied with your work, click “add to cart”, and a more formal review can now be completed once all parts from the project are accounted for.

Now you can simply repeat this process for whatever other areas you need. You can save and share this quote with others who may need to review and approve. If you anticipate needing similar orders in the future, choose the “Save as Quote Template” option in the dropdown box. The next time you have a similar project, choose this option when you start a new quote, then simply make whatever changes are necessary – colors, lengths, quantities, etc. – and you’ll be done with your order in much less time than with previous methods.

If for any reason you need to make changes to a quote, simply use the “Modify Quote” button at the bottom of the quote page.

Be sure to check out the other handy features on the online ordering site, such as related literature, documents and parts at the bottom of each product page and in catalogs. You can also search by keyword or use the navigation at the top for anything you might be looking for.

We hope you’ll take the time to learn the new system. It’s sure to save you innumerable hours in the long run. And if you get stuck or run into any problems, we’re here to help. Refer to the FAQ and don’t hesitate to get one of our sales individuals involved. We are all fully versed on online ordering and happy to help.

Metal panels need attention; they should not be taken for granted. True, they are a notably long-lasting and attractive choice, particularly with the myriad colors and protective finishes available, but once installed, proper care is imperative in order to maintain their durability, performance and good looks for decades.

What are the main culprits of potential damage? Dirt and residue (such as from trees or animals) left to sit on metal panels, for instance, can cause the irreversible degradation of protective coatings, thereby compromising the longevity of roof and/or wall systems. Additionally, corrosive elements, including bacteria, mold, mildew or even acid rain can damage the structural integrity of the panels. Additionally, buildup of foreign elements, such as leaves, can hide potential leak areas or places that may be rotting away. Even in terms of energy efficiency, keeping the panels clean may help a roof reflect heat as they were originally intended.

To keep panel appearance in top shape, protecting the finishes must be a priority—otherwise, you may find yourself needing to re-coat the panels. Stains from leaves and moisture, algae and lime deposits that remain on panels for extended periods can do serious harm to the finish. It should be noted, however, that re-coating should only be considered if the panels remain structurally sound and if doing so wouldn’t void the manufacturer warranty.

How often should you clean metal panels? Most experts agree that at a minimum, an annual cleaning is advisable in order to keep the panels free of common elements that can jeopardize the integrity of the finishes. If you have heavy tree overhang, you may need to clean it or remove debris a little more frequently.

Deep cleaning to remove more stubborn substances (e.g., tree sap, oxidation) can be done every 3 to 5 years, depending on the building conditions, location and weather, etc. Interim, moderate cleanings can also be performed following substantial weather events and seasonal allergen build-up. It’s a good idea, in fact, to assess roof conditions before winter hits to identify any potential issues that need to be addressed.

No matter the frequency, perhaps the most important advisory when it comes to cleaning the panels is to follow the panel manufacturer’s recommendations regarding who should perform the work and with what solutions and tools so as not to void any warranties. In some instances, it may be beneficial (or perhaps even required) to have a professional building surface cleaning company with metal panel experience do the work.

As for the maintenance and cleaning instructions, it’s always best to refer to the manufacturer’s guidelines in order to best protect specific products, for example, to determine which cleaning solutions and techniques work best for a given manufacturer’s panels. Neglect or improper care can degrade the finish, compromising not only the visual appearance and performance but, as noted, can also potentially void the panel warranty. But maintaining the panels doesn’t just entail washing them like you would a car; it also means keeping them free of harmful debris.

Here are a few general tips for the proper cleaning of metal panels (again, refer to the panel manufacturer’s specific directions):

Simple cleaning: generally, water and mild detergent will be sufficient. Do NOT use bleach, which can change the finish color or have a harmful interaction with certain finishes.

Water-soluble dirt or other deposits requiring more complete cleaning: you can use a solution of hot or cold water mixed with detergent. In a container of water, use a 5 percent solution of commonly used commercial (non-industrial, non-bleach) mild detergent. Use a cloth or a soft-bristle brush for application of the cleaning solution, followed by a clean water rinse. Alternatively, pressure-washing with a 40° tip is also an option.

Non-water-soluble deposits such as tar, grease, oil and adhesives: a solvent or alcohol-based cleaner may be required. In this case, since most organic solvents are flammable and/or toxic, they must be handled accordingly. Generally, keep them away from open flames, sparks and electrical motors; use adequate ventilation, protective clothing and goggles; and read the manufacturer’s Material Safety Data Sheet (MSDS) of any solvent used for any other specific safety details.

The following are among the cleaners widely recognized by manufacturers for this type of non-water-soluble cleaning: alcohols—denatured alcohol (ethanol) and isopropyl alcohol (rubbing alcohol); and solvents, including VM&P Naphtha, mineral spirits, kerosene, and turpentine (wood or gum spirits).

For any level of cleaning, do NOT use wire brushes, abrasives, or similar tools that will erode the surface coating and leave scratches or other finish damage that can lead to corrosion. Additionally, always test a small area before proceeding with any of the cleaning agents mentioned to ensure there is no adverse effect resulting from the product’s use.

Remember, the misuse or abuse of any of the acceptable cleaning agents will automatically void any manufacturer’s warranty for the affected surfaces, so be sure to check with the manufacturer and also follow directions on any cleaning products used.

By following the tips above, installers can keep metal panels looking great and performing well for years to come.

To learn more about the importance of cleaning metal panels, contact your MBCI representative or check out our blog post on metal panel maintenance.