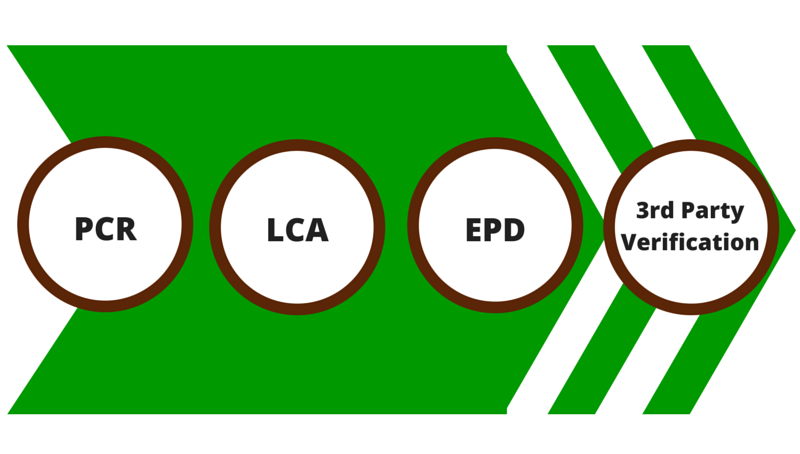

By now I’m sure you’ve heard about PCRs, LCAs, and EPDs. Simply put, a PCR is a set of product category rules; an LCA is a life cycle analysis; and an EPD is an environmental product disclosure. But what do they mean and what’s the purpose of it all? In the broadest sense, these are mechanisms used for the sustainability movement. The most granular is the EPD, which is a product-based discussion (i.e., disclosure) of the environmental effects caused by a specific product or product type. Architects and building designers use EPDs to compare products in order to select the most environmentally friendly products to be used in environmentally friendly buildings.

By now I’m sure you’ve heard about PCRs, LCAs, and EPDs. Simply put, a PCR is a set of product category rules; an LCA is a life cycle analysis; and an EPD is an environmental product disclosure. But what do they mean and what’s the purpose of it all? In the broadest sense, these are mechanisms used for the sustainability movement. The most granular is the EPD, which is a product-based discussion (i.e., disclosure) of the environmental effects caused by a specific product or product type. Architects and building designers use EPDs to compare products in order to select the most environmentally friendly products to be used in environmentally friendly buildings.

Developing an EPD can only happen after the creation of a set of product category rules (PCR). A PCR sets the rules for creating LCAs and EPDs. An example of a PCR is “Product Category Rules for Preparing an Environmental Product Declaration (EPD) for Product Group: Insulated Metal Panels & Metal Composite Panels, and Metal Cladding: Roof and Wall Panels,” which was developed by UL through the efforts of the Metal Construction Association (MCA).

Only after a PCR is developed can a verifiable LCA or EPD be developed. An LCmA and EPD are similar but different. An LCA uses industry-average data, and an EPD is specific to a product or product type. For example, “LCA of Metal Construction Association Production Processes, Metal Roof and Wall Panel Products” provides industry-average information about the environmental aspects of three key products: steel insulated metal panels, aluminum metal composite material panels, and steel roll-formed claddings. This LCA is based on 24-gauge material.

EPDs are typically more product specific. (An EPD is typically based on an LCA, so most often LCAs are developed prior to EPDs.) For example, the EPD titled “Roll Formed Steel Panels For Roof and Walls” provides similar environmental data as an LCA, but includes information about 29-, 26-, 24-, 22-, 20- and 18-gauge materials. This provides additional product specific information that can be used by designers when an industry average is not adequate. And importantly, more LEED points are garnered from a product-specific EPD than an LCA because of the specificity. LEED is certainly a driver of this!

LCAs and EPDs used in the roof industry are often focused on cradle-to-gate analysis, and exclude the use phase and end-of-life phase. Ideally, an LCA or EPD should include the use and end-of-life phases so architects and designers have a complete cradle-to-grave analysis. Without the use phase, designers are allowed to freely select the service life of a metal roofing product, for better or worse, without industry guidance. And, the advantages gained through metal recycling at the end of life are also omitted from MCA’s LCA.

It’s all about standardized disclosure of environmentally based product data.

Learn more about MBCI’s LCA, EPDs and other sustainability efforts, here.