Tag: installer tips

Metal Panel Roof Restoration & Installation

How to Avoid Common IMP Installation Mistakes

Insulated metal panels (IMPs) are ideal for many roofing and wall applications. They are considered a top-of-the-line choice known for their superior insulation value, high performance air barrier, design flexibility, and fast installation. The simplicity of installation creates a high-performance building envelope. The many design options provide a versatile building solution for commercial, industrial, and institutional projects.

Sounds great, doesn’t it? What’s the catch? Well, those benefits won’t mean much if proper care is not taken during the installation process to ensure you’re getting what you paid for. Potential consequences can span the gamut—from minor aesthetic headaches to extremely costly errors such as leaks and structural issues.

Here are some ways to avoid common pitfalls when installing IMP panels on your next metal wall or roof project.

1. Pay attention to the manufacturer’s product installation manuals.

Installation manuals are not just for show! Even the most experienced installer should read, review and understand the installation guide before installing IMPs, and the panels should always be installed in accordance with the project’s installation drawings.

Don’t simply rely on the “what-you’ve-done-before” mindset. Take the time to review the specifics for every individual project. In addition to providing the information needed to execute a successful install, it can also give installers an opportunity to build upon their own knowledge base. One of the most common errors is related to proper receipt and handling of the panels. Investing a few minutes before the project starts and at the start of each day to review key topics helps avoid costly errors and improves production.

If you have a question or something does not seem right stop and call the manufacturer. It is always best to address a problem up front than try and fix a problem after the building is in operation.

2. Equipment check. Do you have what you need?

To keep your IMP installation on track, it’s imperative to ensure you have the equipment you’ll need for the job. Does your project need one or two forklifts, is a crane a better option? Will your project include longer-length IMPs being installed in a vertical orientation? If so, you may need special lifting equipment so as not to damage the panels. Whatever the details, crews need to be prepared to receive a project’s specific materials on site. A little advance planning will ultimately save you time and money by reducing labor and avoiding costly mistakes.

3. Don’t assume every IMP application is the same.

All buildings are not created equal. Just because a construction crew has had experience installing insulated metal panels on past jobs, doesn’t mean they can assume the process will be exactly the same every time. There will always be specific conditions and variables that need to be taken into consideration. Techniques used for vertical industrial panels will be different for horizontal architectural panels.

The vapor barrier (a key function of an IMP) is a great example of how a miscalculation can be problematic. Depending on the panel, the vapor barrier may be applied either at the factory or at the jobsite. If the project calls for a cold storage environment, the “warm” side of the vapor barrier will be on the exterior. Alternatively, a commercial or industrial application generally calls for the vapor seal to be on the opposite side of the panel. Confuse placement of the seal and you’re bound to run into problems down the road.

4. Be on the lookout for creases, buckles and framing alignment.

A crease or buckle on the face of a panel might seem like no big deal, but that couldn’t be further from the truth. In fact, framing alignment is one of the most critical aspects to ensure a proper fit-up of the construction as a whole. In terms of the panels themselves, not only will a framing misalignment not LOOK right but can also cause numerous efficiency and performance issues. Installing inexpensive shims can avoid panels needing to be replaced.

Additionally, make sure the first panel is plum and square, if you start right it is much easier to finish right.

Purlins must be level and square and all framing and bracing should be installed before installing panels. (The IMP manufacturer should specify the amount of tolerances allowed.) Also, take care with caulking and taping, foam-to-foam connections (in order to mitigate potential vapor leaks), seaming, and lap joints.

Attention to detail will avoid costly mistakes.

5. Always think ahead.

Being proactive may be the most important piece of advice construction crews need to hear.

For one, be sure to have a panel surplus on hand. You may be of the mindset that ordering extra panels is at worst a waste or at best, not worth the effort. This is a common judgement error that often leads to installation delays. If a crew has only ordered the exact number of panels needed for a job and there is any damage to the product, whether prior to delivery, on-site or during the installation, there a risk to the project schedule. Waiting on replacement panels can wreak havoc on schedules, especially with panels that may need special manufacturing due to custom components, finishes or colors. What do you do with extra panels you don’t need on the initial installation? Building owners can hold on to any surplus panels to be used as replacements, as needed, over the lifecycle of the building. A little preparation today can go a long way.

Other best practices include understanding the project’s site conditions and ensuring crews remain crews up to date on proper installation techniques—including staying current with training and certifications.

By taking this advice to heart, you can exponentially increase your ability to enjoy the many benefits of IMPs and be confident in your investment. For more information on MBCI’s insulated metal panels and proper installation guidelines, we encourage you to contact your local MBCI representative or visit our website.

Protecting Metal Panels from Rust

One of the many benefits of metal panels that contributes to their strengths is the fact that there are so many rust-resistant coating options with different levels of protection, making them a great option for virtually any environment or any budget. That said, though, missteps during storage, as well as during and after installation, can leave you with unwanted corrosion, i.e. rust. Factors such as improper storage, improper cutting, or other elements the metal might come in contact with can wreak havoc that are beyond the manufacturer’s control.

Regardless of the finish you have—painted, unpainted, high-end coatings or standard coatings—here are some simple installation and care instructions that can help further maintain the longevity of your metal panel product.

Preventing Rust When Materials Are Delivered

Proper material delivery/site storage is the first step to preventing rust. Be certain to check your panels while uncrating after storage on site for any early signs of corrosion, such as black discoloration or white rust/residue on them. This is a sure sign that that panel has been improperly stored and water has not been able to properly evacuate the panel bundles. Do not install any panel on which this has occurred, as the panel finish has most likely been compromised due to improper storage. If you go ahead and install it, that panel is going to continue to corrode and eventually lead to further rust/corrosion.

Make sure that you’re not trapping any sort of moisture in between the metal panels or restricting them from being able to drain when stored on site. Although the panel itself is corrosion-resistant, if you subject it to repeated and significant water being trapped in between the sheets by either not storing the material out of the mud and ground water, or if you’re not sloping the material bundles in such a manner that they can drain, then the result can yield “wet storage stains.” Therefore, if you want to prevent any sort of damage due to improper site storage, you must make sure that the panel is able to drain while stored and, if possible, tarp to resist heavy moisture concentrations such as snow and ice during inclement weather if necessary.

Preventing Rust During Installation

Next, let’s look at some installation no-no’s that WILL most definitely eventually lead to rust—and things to avoid. The first is the accumulation of drill shavings. Whether it’s a roof panel or a wall panel, when you’re installing the screws, even if you’re pre-drilling for the screws, you’re going to generate metal shavings. If those metal shavings are not removed and left to sit or cling to the sheeting those shavings will rust and will stain the roof or wall sheets. The shavings are uncoated/raw metal with no corrosion protection that can and will rust quickly. Eventually, the shavings may wash off or be blown off the roof or wall, but might not be until after they’ve stained the sheeting, thus leaving you with an issue to remedy and, since the “culprit” is gone, questioning if it’s just a stain or something more serious.

Remove the shavings as soon as you can to mitigate this issue. Additionally, if you’re going to do any field cutting, you need to do so via a shearing process utilizing the proper tools, such as electric nibblers, hand snips or electric shears. Any other type of cutting can cause the edge of the base material to become exposed and no longer protected by the Galvalume and painted coatings as they become disrupted. Using tools such as a “hot” saw, abrasive blades or even a reciprocating saw leads to a tearing motion rather than shearing motion, which will strip the metal of that protective coating; over time it can start to rust.

Graphite is another corrosive element that should be avoided as it is not a friend to Galvalume metals. Therefore, stay away from writing on your Galvalume material with pencils because over time the graphite will react, break down that protective layer, and lead to corrosion. If you do write on the panels with a pencil, make sure you clean it off. The best solution is to use permanent markers/Sharpies or dry erase markers.

Watch out for overspray from any adjacent wall coatings or finish systems like Stucco or similar masonry products, which can also damage panels if not removed promptly. And be certain not to rest the base of any metal panel in direct contact with material that is corrosive, such as concrete, or in such a manner that water can become trapped behind the panel and not able to drain. Industry recommendation is to maintain an eighth of an inch to a quarter-inch gap at the base of all your wall panels for not only expansion/contraction but for proper drainage and to prevent contact with dissimilar/corrosive materials.

Preventing Rust After Installation

Although Galvalume—whether bare or painted—is highly corrosive-resistant by nature, it too has its Kryptonite. Post-installation, the most important thing is to make sure you’re not adding something to the roof that’s going to react chemically/negatively with the Galvalume finish/coatings. For instance, many people don’t recognize that if they have mechanical units on a roof, the condensation that comes out of those mechanical units, when deposited directly onto a Galvalume panel over time, will lead to corrosion and rust. This condensate should either be filtered before exited onto the roof panel or drained via piping and not directly onto the sheeting.

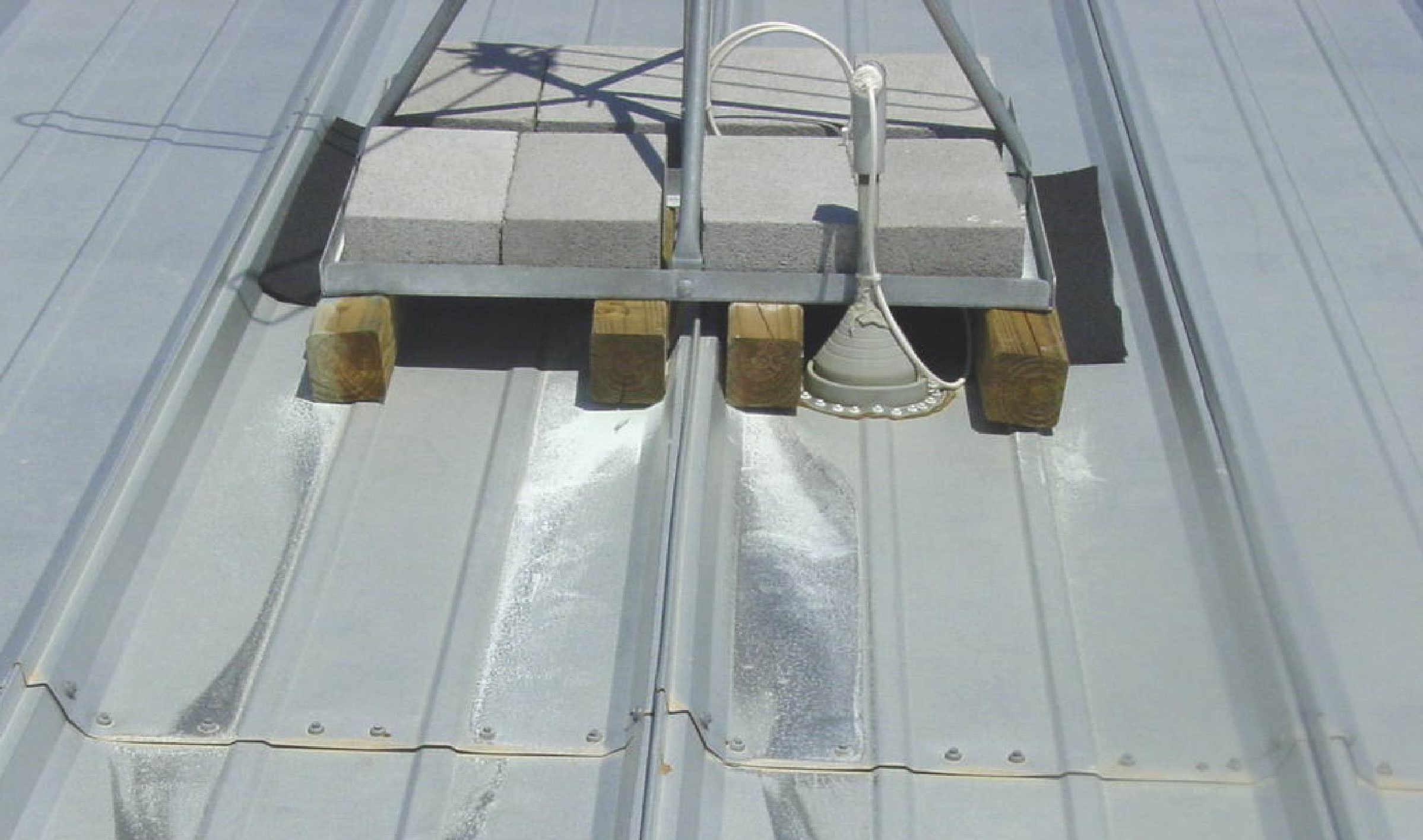

Contact with dissimilar metals, whether it be via incorrect type or method attachment from metal signage, solar panels and snow retention can be another major factor in post-installation corrosion. Panels must not come in contact with or be exposed to the runoff from the following metals: copper (lightning arrest systems, flashing, roof jacks, HVAC drainage); lead (roof jacks, pipe flashing); iron (pipes or soil); and, as previously noted, metal shavings.

Post-installation, panels must also not come in contact with or be exposed to the runoff from chemicals, such as acid from batteries and acid washing brick, and even pressure-treated lumber.

What To Do In Case of Rust

Let’s face it. Sometimes, despite all your efforts…someone didn’t get the memo and rust happens. Now what do you do? How can you safely can attempt to repair it or remove it without causing more damage?

First off, here’s what NOT to do. Heavy solvents that are meant to remove paint or stains can/will adversely affect the metal. If you witness a rust stain on the roof, don’t go up there with paint remover, acetone or any other toxic solvents and start scrubbing on it because you most likely could make matters worse. You might remove the stain along with the finish entirely, leading to bigger problems. (If you’re an end user, check your finish warranty and manufacturer maintenance documentation supplied to you by your builder/installer for guidance on cleaning and repairs.)

The key is to identify if the rust is just a stain /discoloration or it’s more systemic. Is the catalyst (ex.: a shaving) causing the rust still present? If it’s just a surface stain and the coating hasn’t been damaged, it might just be a matter of getting some mild detergents or something else to remedy the situation. Some good options are Formula 409 or Simple Green and Soft Scrub without bleach or something similar. and it may require a trial and error process to determine which is most effective based on the condition you’re trying to remedy. Products such as Rid O’ Rust or similar whose key ingredient is oxalic acid can be used diluted with water. With any of these products, test a small area first and wait to see results before proceeding to larger areas. And always be certain to fully rinse/flush areas of cleaning products to ensure no residues /films remain.

Always start light. Don’t break out any steel wool and/or metal grinders and start trying to get the rust off the panel that way. If it looks to be more than just a stain—perhaps you clean it and a few weeks later it comes back—that most likely means that the panel has actually been damaged and you’re not just going to get rid of the “stain” by cleaning it as it’ll return. It may require touchup paint or even a panel replacement. It depends on the severity of the damage. If this is the case, be certain to check with your installer, maintenance manual, and panel supplier for further instructions on how to address.

For more information on panel maintenance and warranties, see the MBCI website resource center.

Measuring for a Metal Roof: Considerations and Tips

Getting an accurate measurement for your metal roofing panels may seem like a no-brainer, but it’s not quite as simple as length x width. The many complexities of a roof must be taken into consideration in order to ensure your numbers add up. For instance, anything that intrudes upon a roof plane needs to be included in drawings with labeled measurements as these conditions will all affect the measurement but are sometimes overlooked.

Let’s look at some specific conditions to consider before getting out the measuring tape as well as some handy tips for installers.

Building Conditions to Consider Before Measuring

The type of roof system

Is it going to be a standing seam roof system or an exposed fastener system? Once you’ve decided on your roof type, we recommend reviewing all of the conditions/details on the roof. If it’s a standing seam roof, will the roof system need to float? If so, where will it be pinned, and what direction will it float?

At MBCI, we have published installation technical manuals for installers and erectors to utilize in order to familiarize themselves with how to adjust for ridge conditions or end lap conditions, for instance.

Is it a new or existing metal building?

If it is an existing building, are there new or updated building codes to consider? This could possibly dictate panel type, gauge, or width, or require additional framing members that could impact the final measurements.

What is the purlin spacing?

The panel break at the purlin for an endlap condition will need to be considered.

Are there extensions, overhangs or penetrations?

Include any roof extensions or overhangs that may not be apparent at first glance. Any and all roof conditions should be considered when calculating panel and trim length, including any roof penetrations such as pipes, roof curbs, skylight hatches, etc.

The manufacturer’s details will aid in determining such things as panel hold back at the ridge, or panel overhang at the eave or gutter. Also, roof or slope transitions, and panel hems should be considered.

Insulation

The thickness of the insulation could determine or dictate the fastener type used.

Measuring Tips

- Field verify the roof slope. The contractor should gather the field dimensions so measure when the framing is in place. While you can measure off of a set of plans, it’s not a definitive way to do things because things change in the field.

- The structure should be square while you’re measuring. Scaling from plans may get you close, but measuring erected framing that is plumb and square is the most accurate.

- You should measure multiple spots.

- It’s a good idea to use a plan view of the roof or sketch a bird’s eye view to record your measurements.

- Record your measurements in the units of measure that your manufacturer uses, typically feet and inches, to avoid errors.

- The erector may elect to add a few inches to the length of the panels at a hip or valley to remedy any cutting mishaps since these panels will be field cut to the hip or valley angle.

- Some contractors include one or two extra panels at the longest length for any errors or jobsite damage.

Ultimately, the takeaway is that any differential when measuring metal panels for installation could affect a building’s performance, so it’s important to keep all potential scenarios that could affect measurement accuracy in mind—throughout the entire process. To find out more about the proper way to measure a roof for metal buildings or to schedule training, contact your local MBCI representative.

Five Installer Responsibilities for Weathertightness Warranties

Every metal roof installation comes with an implied warranty: the roof shouldn’t leak. This is true even if your customer didn’t buy a “manufacturer’s weathertightness warranty.” It’s just the very basic expectation. Any details we send out, any materials, whatever the manufacturer supplies the installer…all go to that simple premise that you are buying a quality roof system from the get go.

Beyond that, though, a purchased manufacturer’s weathertightness warranty takes it a step further. It’s added insurance. In order to get the full value and peace of mind from a warranty, there are certain considerations the installer needs to keep in mind. Let’s take a look at five key installer responsibilities on projects with manufacturer weathertightness warranties—beyond, of course, putting down the roof correctly!

1. Understanding the weathertightness warranty type selected for the project.

MBCI sells two types of weathertightness warranties: Standard and Single Source. The approval process up front is the same for both but it is crucial to know the scope of the project’s warranty. With a standard warranty, the only real expectation is that the roof will remain watertight for 20 years. It is a very basic, very inexpensive warranty in which the manufacturer and the installer jointly warranty the roof for that period of time. The manufacturer covers all the materials and the details, and the installer is covering the installation.

The opposite end of that spectrum is the single source warranty, which is purchased when the customer wants not only the roof warrantied, but prefers everything associated with the roof—any accessories, anything else penetrating the roof—to be 100 percent covered by the manufacturer, if applicable. These warranties do cost more, require inspections, and require an installer to have completed the manufacturer’s certified installer training program.

It’s important for the installer to know what warranty was sold, particularly because he/she may not have been the one involved from the start. They may be coming in to bid the job as the installer only. Therefore, he/she needs to ask questions because they may or may not have the personnel on their crew that meets the requirements to install that roof for the weathertightness warranty purchased.

2. Obtaining/confirming building geometry approval for warranty.

Beyond the type of warranty, it is simultaneously necessary to investigate whether there are additional procedures related to the building geometry. Has everything been correctly noted so that the warranty itself will be valid? Is the manufacturer aware of transitions, edge conditions, roof penetrations, roof accessories (snow guards, solar, etc.)? It is extremely important to make sure that the geometry—or the conditions of the roof—are covered within a particular warranty.

MBCI, for instance, will review your roof plan and see the eave gutters, the ridge, the rake, etc. and we can survey what’s going on. Is that roof tying into something else? Will there be materials on that roof that aren’t provided by us or not being installed by the roof installer? As the manufacturer, we would be taking a cursory view to say, yes, we can warranty the roof or no, revisions are needed. If there is anything that we can’t warranty, we’re going to spell that out upfront. We will give as much direction as possible to get the project to a point it can be warranted.

That said, it’s the installer’s and customer’s responsibility to make sure that the manufacturer knows what’s happening. Think about it this way. Many times, there are other trades involved outside of the roofing contract. Along comes someone who says, “I need to run something through your roof,” or six months down the road the owner wants a satellite dish on the roof and the installer incorrectly penetrates the roof., causing a leak. Guess who they’re going to call? The installer/customer/owner needs to get that approved by the manufacturer. Otherwise, the warranty could be voided.

The main takeaways here: Do not make modifications to that roof without the manufacturer’s approval because the roof installer can end up inheriting the liability for that if they do. And, communicate the criteria or the requirements of the warranty to the customer. Don’t just hand them the paperwork. Make sure they understand what’s in it and their responsibilities as metal roof owners.

3. Ensure proper installer certification and training as required by the warranty type.

This sounds self-explanatory, but it goes back to the warranty type and the necessity to make sure the warranty selected is appropriate for the job. Verify whether or not the job requires a certified installer and if so, ensure certifications are current. If the installer is not certified, then they need to take the steps to get certified in order to meet that warranty requirement.

A common situation: A warranty gets sold by a general contractor and he/she subs it out to another roofing contractor. That sub comes in and says not to worry, “we know how to put the roof on. We’re certified.” Then, MBCI gets ready to issue the warranties or schedule inspections and finds out the subcontractor doesn’t know our system that well. And remember—for certain types of weathertightness warranties the installer needs to be certified via our training program.

4. The installer is responsible for correct installation per manufacturer’s details.

The onus is on the installer to follow the details and directions provided by the manufacturer. If you install the roof per those details, and then there’s a problem, the responsibility falls back on the manufacturer unless determined otherwise. If, however, the installer doesn’t follow the details provided and the manufacturer comes out to do a warranty claim or warranty inspection, then the installer is going to be responsible for correcting it. The installer can’t put it in wrong and just say, “oh, well, that’s covered by the warranty.” It’s not. A manufacturer’s warranty is not for covering a bad installation—particularly in the case of a standard warranty. If the installer does a poor install and the roof leaks, that’s not covered by the standard warranty; it falls back on the installer. Of note, this scenario can be different with a single source warranty, since the manufacturer will be out there doing ongoing inspections and ultimately can become responsible for the installation as well.

And, it goes without saying, the warranty doesn’t cover the interior contents of a building that may be damaged due to an installation issue.

5. Do not make adds or changes to an installed system once completed and the warranty has been issued without first getting manufacturer approval.

The warranty only covers the installed product per details, as mentioned. It does not cover additional materials added to the roof or any changes made, at least without the manufacturer’s prior approval—after the install is complete.

Some examples would be adding a mechanical unit to the roof, a plumbing vent added through the roof, or the satellite TV cable through the roof. Putting a penetration, fasteners, holes of any kind, into a previously installed roof system, unless approved by the manufacturer, will void the warranty in that location. If the manufacturer does not give approval, the installer, along with the customer, would need to make the decision—is it worth the risk to proceed knowing that if the roof leaks, that location would no longer by covered by the warranty.

To find out more about MBCI warranties and installer certification, contact your local MBCI representative or visit our website.

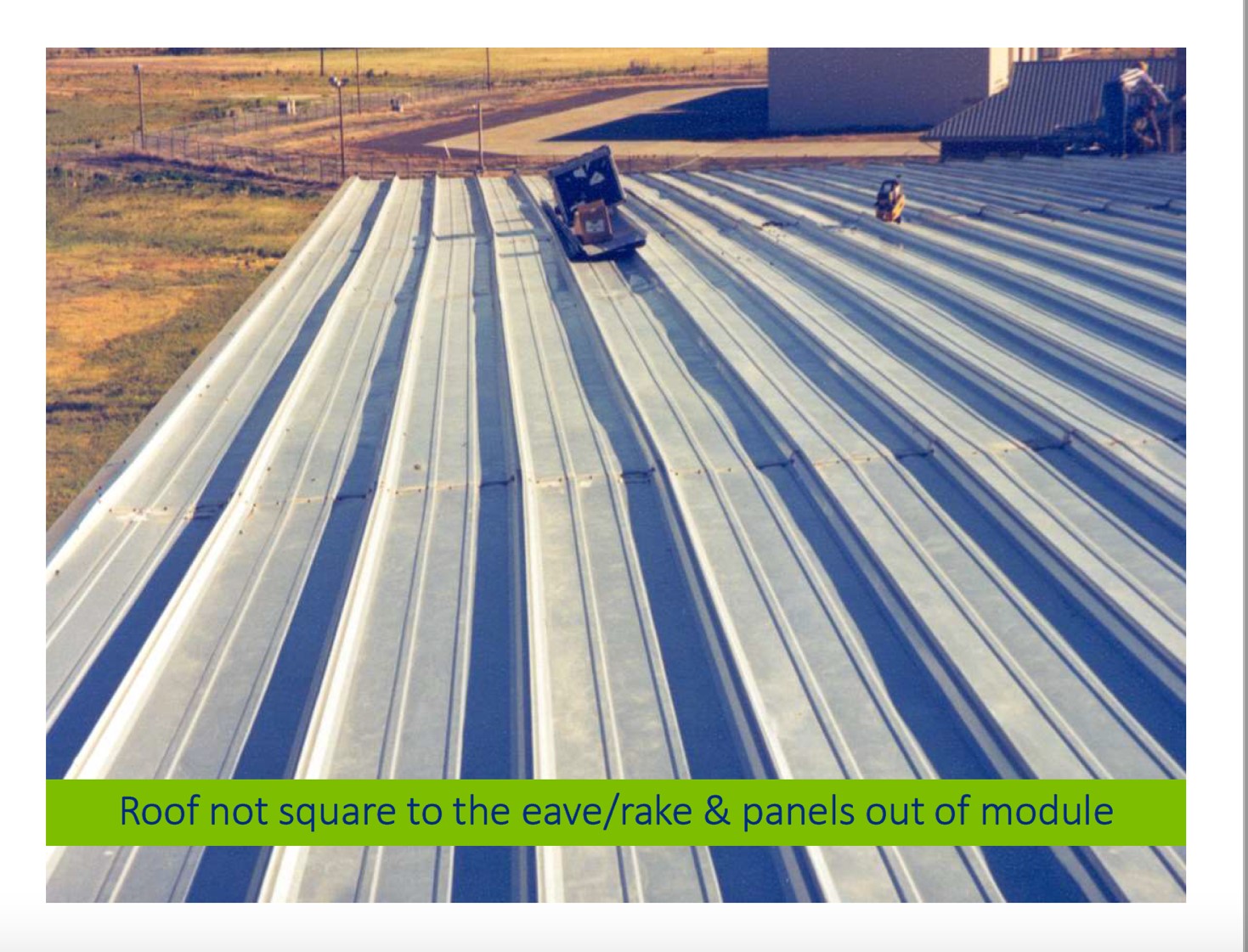

Maintaining Panel Modularity and Square When Installing a Metal Roof

Most metal roofing system installers know the importance of keeping panels on module, i.e., holding the width of the panel. But holding module alone isn’t enough; keeping panels square is equally important as the two go hand in hand. When proper attention is paid to both, you will have a faster install—ensuring longevity and functionality of the roof system so that it will be able to properly expand and contract as designed—not to mention improved appearance.

The ability to hold panel modularity is directly dependent upon several factors, including:

- Skillset of the installer

- Frequency that modularity is checked

- Substrate deficiencies

- Insulation system

- Appropriate methods being used to hold panel modularity during panel installation

- Keeping symmetry/maintaining squareness

Here are some important considerations for ensuring success for panel alignment.

The Relationship Between Holding Module and Squareness

The roof panel is not going to “hold itself” 100% on module and square by installing just as received using only the hardware components supplied from the manufacturer. It is the installer’s responsibility to ensure the proper alignment and squareness of the panel install in order to hold panel module. For example, if you’re working with a 16-inch panel, installers need to keep the spacing of the panel ribs at 16 inches. In this way, the panel doesn’t become stretched or compressed. So, holding module is key along with holding square; the two are connected. If an installer doesn’t start the building out square, it will make it even harder to keep module with regards to the alignment of the panel.

As far as the overall appearance and performance, the success of the metal roof is going to be heavily dependent on how square it is installed and an ability to maintain proper modularity. There are a number of suggested methods for doing so outlined below. Installers must decide which method works best for their them and their roof panel application.

Methods to Ensure Success

The key method is measuring ahead and monitoring your installation so you know where you should be along that roof install. The metal panel is typically 24-gauge or 26-gauge material and therefore it’s easy enough to pull it ahead or have it become crowded during installation if you’re not staying close to your marks, and therefore it’s easy to get the panel out of module. The bigger impact, aside from just aesthetics of being on or off module is the performance of the system itself, to where it could become under stress or it could go through extra deformation due to being out of module and out of square. Its important to verify/measure the panels leading edge and adjust as needed via roof clips or other panel hardware. Some suggested methods include:

- Run a string line from eave to ridge square to the eave and measure from the string back to each panel run. The string line is moved ahead as the roof installation progresses. If installing over solid substrate, snap chalk lines for alignment points along the roof.

- Use a metal measuring tape permanently secured to the substrate at panel endlap locations, ridge and other intermediate points for permanent reference to check module.

- Mark the eave line for every rib installation to ensure the panel stays on module. Trapezoid panels offer metal closures for proper placement at the eaves to assist in holding module while vertical rib panels do not.

- Pre-drill substrates at the endlaps and ridge locations for clip alignment ahead of roof panel installation. A hole can be located at the leading edge of clip location so that an awl or punch can be inserted into the hold to align the clip and adjust accordingly. The holes drilled ahead of the panel at the corresponding panel module.

To assist with holding the panels’ shape when checking modularity, utilize outside panel closures or cut wood blocking to the panel’s correct width and insert between panel ribs. Note that a bad roof substrate that is out of tolerance for “flatness” will not be hidden or magically corrected by the panel installation. The alignment and tolerance of the substructure are equally critical to the panels’ squareness and being able to hold module. Substrate should be should be installed to a level plane tolerance that is no more than ¼” in 20-ft or 3/8” in 40-ft variance.

Do not stand in panel and/or keep as much weight as possible out of panel while installing clips. Not only is it unsafe but it changes the width of the panel and thus impacts modularity.

Use the correct combination of roof clip heights, insulation thickness and thermal spacers to maintain level panel installation and prevent panels from gaining or losing module. MBCI provides recommendations in its installation manuals regarding most common types of insulation thickness and means of attachment to various substrates. Additionally of note:

- Trimming of insulation or adjusting thermal block thickness can help control/modify panel modularity as needed.

- Alignment straps for trapezoid panels can be purchased from the manufacturer and installed on top of purlins before insulation. These set the clip spacing at 2-0” o.c and can be utilized at the endlap and ridge locations minimum or added at other locations.

At MBCI, we recommend that installers check module/square every three to four panels. If the panel grows or shrinks 1/8th of an inch or 3/16th of an inch with three or four panels or shows signs of being out of square, there’s time to recover from it by making adjustments to correct. If an installer just blindly puts the roof on for 50 feet or so and then realize they’re off module or out of square, it will likely be past the point of return to hold module and keep square.

For more information on installing metal roof panels to hold module, see our previous blog post on the topic.

For more information on our installer training sessions, click here, or submit your technical or installation questions by filling out our Ask An Expert form here.

Cutting Metal Panels Properly On Site

Cutting metal panels on site is an often-necessary part of installing metal roofing and wall panels. However, using the right tools and methods to ensure the panels remain damage-free is vital. Using the wrong tools can result in rust, rust stains, the voiding of warranties and diminished building service life. In this blog post, we’ll share several common field-cutting techniques and best practices that help ensure good results.

Maintaining Longevity When Cutting Metal Panels On Site

When metal panels are made in a manufacturing facility, the tools and methods used to cut the coated metal coil help protect the cut edge from deterioration like corrosion. When cutting metal panels on a jobsite or in the field, protecting any cut edges is just as important. To understand how to field-cut metal panels without sacrificing the quality and protection delivered from the manufacturing facility, you must first understand the what protects the panels. Most often, metal roof and wall panels are fabricated from Galvalume®-coated steel coil because of its proven longevity. Not only does the Galvalume coating protect the surface area of the metal panels, it has also been shown to be effective along the thin edges of the metal too, as long as those edges are cut properly.

During fabrication, the Galvalume metal panels are cut to length either by shearing while flat before entering the roll former, or by means of a profile shear as the panels exit the roll former. Either method tends to “wipe” the Galvalume coating across the cut edge of the metal panels. This provides superior cut-edge protection from corrosion.

Likewise, when panels arrive on site, any needed field cutting should address the same concerns of protecting the edge of the steel from corrosion. Of course, there are ways of doing the field cutting correctly. However, there are also poor strategies that can lead to real problems. The following are examples of common field cutting tools and the best practices for good results.

Common Tools and Methods for Cutting Metal Panels On Site:

Aviation Snips

Red and green aviation snips are a good choice for small cuts on metal panels, such as around pipe penetrations. These snips will wipe the Galvalume® coating in the same way as factory shears, making them a good choice.

Electric Shears

Electric shears are optimal when making lengthier cuts along the steel, such as cutting a wall panel at a corner or at a door opening. These shears take a ¼” strip of metal out of the panel during the cutting process, which tends to leave both sides of the panel smooth and flat along the cut. Like the aviation snips and factory shears, electric shears will wipe the Galvalume coating and protect the edges.

Mechanical Shears

Mechanical shears are an add-on tool that fit onto a battery-operated impact or screw gun. These shears do not take any metal out of the panel and will leave a slightly wavy edge. Mechanical shears are an excellent choice for bevel cutting standing-seam panels at hips and valleys, since they too wipe the Galvalume coating over the cut edges to offer protection.

Nibblers

A nibbler is a great tool for cutting across corrugations in wall panels to create openings for windows, doors and similar structural additions. A good nibbler typically costs $500-$700 (currently), but is well worth it if you often cut corrugated metal panels. The punch and die in the nibbler tends to wipe the Galvalume across the cut edge as it punches out small, half-moon shaped pieces of panel. However, because these little metal pieces will fall away from the cut, it’s important to contain them so no one walks on them. Otherwise, they can embed in the soles of installer’s shoes and create scratches in roof panels when they walk on the roof.

Skill Saw

Skill saws are an ideal tool for cutting metal panels because of their versatility. This tool can cut either across or parallel to corrugations, whether straight or at an angle. When using a skill saw, it is critical to use a saw blade that cuts cool. Otherwise, the Galvalume coating can melt along the cut edge and become ineffective. In particular, do not use an abrasive blade, which will generate heat and damage the coating.

Additionally, its vital to avoid cutting panels on the roof or above other panels. A skill saw blade will throw considerable amounts of steel debris into the air and down onto any panels below. This debris, called swarf, will quickly rust and ultimately cause rust spots in the panels. If enough swarf gathers in one spot, it can rust through the panel.

Steel swarf, like this collected at the ridge will rust through the panel.

Which Tools Should To Avoid When Cutting Metal Panels On Site:

Tools that should never be used include:

- Torches

- Cut-off saws

- Reciprocating saws

- Hacksaws

- Grinders

All of these tools will melt the Galvalume® coating, causing edge rust just like an abrasive blade would. These tools also throw a lot of steel debris (swarf) onto the panels they cut. This debris will be hot and will embed into the panel coating. This can cause rust spots and bigger problems down the road.

In conclusion, using the right tools and following metal panel manufacturer recommendations when cutting metal on site will help ensure that the panels remain damage-free and the final installation will be a fairly seamless process. Using the wrong tools can result in rust, rust stains, and the voiding of warranties. For more on best practices and recommendations for on-site cutting and installation of metal panels contact your local MBCI representative.

Are Metal Panels An Ideal Low-Slope Roofing Material?

Many large, commercial, low-rise buildings often don’t benefit from steeply-sloped roofs the way residences and small commercial buildings might. This is because a steep roof slope would add unwanted height and unnecessary construction cost. Buildings like warehouses, retail stores, etc. are more appropriately built with low-slope roofing, commonly known as “flat roofs”. The National Roofing Contractors Association (NRCA) defines low-slope roofs as those with “a slope at or less than 3:12″. Anything steeper qualifies as a “high-slope roof”. With this in mind, let’s look at some key points to consider when designing and constructing a low-slope roof.

Low-Slope Roofing Materials

When it comes to selecting low-slope roofing products, there are generally three fundamental choices:

- Asphalt/ Bituminuous Products: The traditional commercial roofing norm for many years, the use of asphalt/bituminous products has dwindled as newer, more appealing options have emerged.

- Flexible Membrane Roofing: This roofing material can be made from a variety of types of plastic/polymer-based materials (commonly known as EPDM, TPO, PVC, etc.). Rolls of the chosen membrane are laid out on the roof structure and secured in place either with mechanical fasteners (screws with large washers) or with a continuous layer of adhesive.

- Metal Roofing: Sometimes overlooked, metal roofing is suitable for different roof slopes. Many metal roofs that use standing-seam systems are rated for use with a pitch as low as ½:12.

When considering which type of roofing material to use for a building project, there are a number of significant differences that illustrate why metal roofing is often the ideal choice.

Engineered For Superior Performance

Standing-seam metal roofing is made specifically for use on low-slope roofs as it meets a number of performance requirements:

- Water resistance: Precipitation doesn’t penetrate through metal or through the standing seams where the metal panels join together. This is why they can tolerate such low slopes, allowing the water to drain away slowly and predictably without leakage.

- Rigidity: The rigid nature of metal means that there is less opportunity for ponding (standing water). This is not always the case with asphalt/bituminous or membrane roofing systems.

- Drainage: Metal roofs carry water to the building’s edge toward gutters and downspouts that carry it away from the building. Other roofing systems rely on drainage piped inside the building. This takes up space and has the potential to leak water inside the building and cause damage.

- Wind Resistance: Standardized uplift testing shows that metal roofing performs as well or better in extreme weather than mechanically-fastened or fully-adhered membrane systems.

- Durability: The most cited advantage of metal roofing is its long-term strength and durability. Engineered design and use of high-quality coatings ensures a longer lifespan—50 years or more. In contrast, other roofing types typically feature lifespan ratings of 20 or 30 years.

- Puncture Resistance: Low-slope metal roofing is more puncture-resistant than asphalt/bituminous or membrane roofing. This makes it better able to tolerate foot traffic, hail and other puncture-inducing hazards.

- Construction/ Installation Ease: Metal roofing panels are custom-made to suit specific building sizes and end uses. This customization typically means it takes less time to place and install metal roofing in the field. Further, metal panels can tolerate a wide range of temperatures and weather conditions and still install and perform as intended. Low-slope roofs are also safer to walk on with less risk of slips, falls and other hazards.

Cost-Effectiveness

Using metal roofing on low-slope roofing systems can be cost effective in a number of ways:

- Fewer labor hours as a result of the ease of installation saves money during construction.

- Competitive material costs, particularly if the metal roofing is part of a total metal building package from a single manufacturer.

- Minimal maintenance requirements and aversion to rusting, mold growth and decay that save the building owner money over time.

This all adds up to a very favorable life-cycle cost.

The performance, cost-effectiveness and life-cycle benefits of metal roofing panels make them a viable option for low-slope roofing systems. Manufacturers like MBCI can help you select the right metal roofing products and provide information and resources to help ensure proper installation.

View examples of low-slope metal roofing projects and contact your local MBCI representative to start your project today.

Metal Roof Seaming: Best Practices for Ensuring Weathertight Seams

It would seem logical that the most important field installation process for a standing-seam metal roof is the actual process of creating the weathertight seams that connect the metal panels together and ensures the structural integrity of the roof. Perhaps for many different reasons, however, this critical seaming process is not always given the proper attention it deserves, nor are installers given the proper training required to ensure installation runs smoothly. This approach can cause some serious issues, not the least of which is the voiding of a manufacturers warranty or the discovery of roof leaks and the resulting damage.

To help, here are some best practices for readily and successfully carrying out the metal roofing seaming process:

Personnel

Because of the critical nature of seaming metal roofs, the crew members doing this work should be properly trained. Team members who will be performing this work should not perform the seaming without having participated in the appropriate installation training required to ensure the seaming process is appropriately managed. Most roofing manufacturers offer installation training that many installers take advantage of—and this training opportunity should be taken advantage of by the staff who will be doing the seaming.

Seaming Equipment

It is very important that the seaming equipment being used is matched to the specific roof panel system being installed. Manufacturers routinely rent out this equipment in order to be sure that the metal panel profiles are installed properly and are not compromised through the use of generic equipment or that of another manufacturer. Using the wrong equipment can end up being costly for everyone if panels and seams are ruined in the process.

Hand Crimper

As metal panels are set in place, they are often secured with metal clips, spaced according to engineering and construction needs. Hand crimpers are used to form the seams around the clips as well as any end laps. This process must not be overlooked as improper hand tooling is the number one cause of faulty seaming. To ensure costly mistakes aren’t made, follow the process described in the “Field Seaming Tool Manual”. This manual should be provided with the equipment and reviewed in training.

Electrical Sources

The next step will involve the use of an electric seamer which obviously needs a source of electricity to operate. However, not just any electrical power source will do. Almost all professional seamers have an AC/DC motor that will require 10 or 15 amps and 120 volts. A dedicated electrical circuit—preferably from a temporary electrical pole or an existing building electrical panel—is the best and most reliable way to go. A generator with 15 amp capacity dedicated to be used only for the seamer (in order to avoid power surging) may be acceptable as well. In either case, the power line to the seamer needs to be 10-gauge (minimum) cord. It should also be no more than 200 feet long (to avoid power drop).

Electrical power sources that are NOT acceptable include outlets from a powered man lift or a generator that is not dedicated to only the seamer. (This includes a generator that is part of a welding machine.) Check the manufacturer’s requirements for any other restrictions that can damage the seamer. Skipping this step can place the responsibility for repair or replacement onto the installer.

Electric Seamer

Once all panels are in place, the hand crimping is done and the power source is set. Then, electric seaming takes care of finishing the roofing system. Again, consult the seamer manual for proper procedures, including which direction the seaming should be done. (Seaming can either be done up or down the roof depending on direction of roof installation.) The electric seamer includes a switch for the operator to control the starting and stopping of the process.

On low-slope roofs, the operator should walk alongside the seamer to be sure nothing is in its path and that the seam is done properly. While stopping and re-starting is fine, the seamer should never be removed in the middle of a seam. Doing this makes it very difficult to set it back in exactly the same spot again. If something appears to be wrong with the seamer or the seams being produced, then don’t keep using it. There is no point in damaging multiple roof panels if any one panel indicates that things aren’t going right. In this case, contact the manufacturer right away for assistance or replacement of the seamer.

Safety

Electrical seamers are heavy and—if not used and secured properly—can cause harm or injury. Therefore, they should always be tied off with a safety line—the same type used for workers—not a common rope and definitely not the electrical cord. The safety line should be properly secured to the seamer and then attached to something rigid on the building. Never attach this to a person who could be pulled off of a roof by it.

Cleaning

Before use each day, check the electric seamer and remove any oils, debris or dirt. Make sure the seamer is unplugged from the electrical power source before you begin cleaning. Also, check the grease level in the machine daily and only add a little bit (2-3 pumps from a grease gun) as needed. Too much will cause the grease to leak out onto the roofing.

Following these pointers should help assure the safe and efficient use of the right seaming equipment when installing roofing panels. To find out more about proper seaming or to schedule training, contact your local MBCI representative.