Panel Repair Technical Bulletin

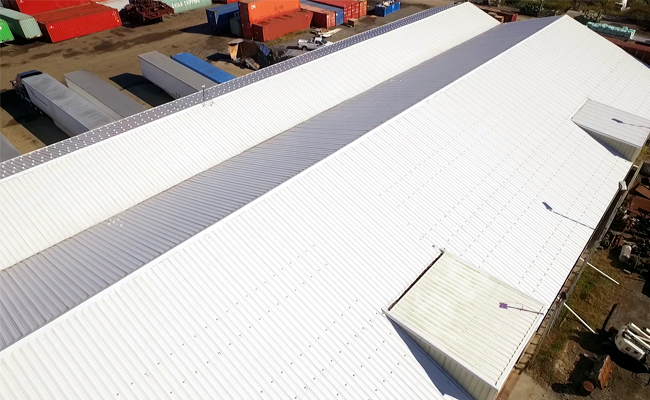

In our prior blog post, Benefits of Roofing Retrofits with Metal Roofing Systems, we looked at the benefits associated with retrofitting an existing building with a new metal roofing system. In this discussion, we will look at several ways to do it.

Buildings with flat roofs can be retrofitted with light-gauge steel framing systems to create a new sloped metal roof. Such systems can be installed directly over existing roofing membranes and structures, subject to appropriate structural engineering review. These systems typically use light-gauge (16 gauge to 12 gauge) steel framing installed directly above the existing roof to create a sloped plane. Regardless whether the existing roof structure is steel, wood or concrete, the new, lightweight framing system can be designed to disperse roof loading appropriately and connect securely.

The physical footprint of the existing roof, the type of framing system employed, and any special rooftop conditions will typically control the final geometry of the new sloped roof. A low-slope application (less than 2:12) can be selected based on economy and configured to discharge rainwater off of the roof. High-slope applications (greater than 2:12) are typically selected to improve and update the look of an existing building while improving long-term performance. Once the metal framing system is in place, then standing seam metal roof panels are commonly installed, creating a ventilated attic space in the process.

Low-slope metal roofing can be a great choice when a fairly utilitarian solution is needed for improving overall roofing performance. Exposed fastener systems can be used to allow direct installation of the new roofing panels over existing metal roofing or some other materials. Roofing panels specifically designed for retrofit applications typically have a rib spacing of 12″ on center with a rib height of just over an inch. The minimum slope for such a panel is 1/2:12. Any existing lap screws must be removed from the existing roof before the new panels are installed. The new retrofit panels are then attached with screws that fasten through the existing panel major ribs and into the existing purlins.

In some cases, an existing sloped roof may have another roofing material in place that is nearing the end of its service life. In that case, a new long-lasting, standing seam metal roofing system can be installed directly over the existing roof. Some systems will require a simple sub-framing system that allows the new roof to be installed directly over the existing. Retrofit roofing systems such as this can be UL-90 rated and FM Global rated. Other strategies exist to increase the energy efficiency of the building when adding new standing seam roofing, such as adding unfaced fiberglass insulated between the existing and the new roof and to vent the cavity between the old and new roofs by adding vent strips at the eaves, plus a vented ridge to allow air intake and exhaust. This method works well with roof slopes of 3:12 or greater.

Regardless of the specific system selected and designed, installing a retrofit metal roofing system allows the existing roof to remain in place, which saves on labor costs. It also minimizes the chance for water entry into the building during the roofing process and provides for a safer working environment. Existing rooftop equipment, vents, or light-transmitting panels can be accommodated by any of the systems described.

According to the Metal Construction Association (MCA), “retrofit metal roofing represents an economical and functional solution for building owners who want to beautify their existing structure or correct performance issues related to aging roofs and out-of-date materials. They have been employed in millions of square feet of existing commercial, industrial, retail and education facilities. The result is a new code-compliant metal roof that will last for 60-plus years, providing higher energy efficiency by reducing heat gain through the roof in summer months and reducing heat loss during winter months.”

To find out more about these retrofit systems, contact your local MBCI representative.

Insulated metal panels (IMPs) are ideal for many roofing and wall applications. They are considered a top-of-the-line choice known for their superior insulation value, high performance air barrier, design flexibility, and fast installation. The simplicity of installation creates a high-performance building envelope. The many design options provide a versatile building solution for commercial, industrial, and institutional projects.

Sounds great, doesn’t it? What’s the catch? Well, those benefits won’t mean much if proper care is not taken during the installation process to ensure you’re getting what you paid for. Potential consequences can span the gamut—from minor aesthetic headaches to extremely costly errors such as leaks and structural issues.

Here are some ways to avoid common pitfalls when installing IMP panels on your next metal wall or roof project.

Installation manuals are not just for show! Even the most experienced installer should read, review and understand the installation guide before installing IMPs, and the panels should always be installed in accordance with the project’s installation drawings.

Don’t simply rely on the “what-you’ve-done-before” mindset. Take the time to review the specifics for every individual project. In addition to providing the information needed to execute a successful install, it can also give installers an opportunity to build upon their own knowledge base. One of the most common errors is related to proper receipt and handling of the panels. Investing a few minutes before the project starts and at the start of each day to review key topics helps avoid costly errors and improves production.

If you have a question or something does not seem right stop and call the manufacturer. It is always best to address a problem up front than try and fix a problem after the building is in operation.

To keep your IMP installation on track, it’s imperative to ensure you have the equipment you’ll need for the job. Does your project need one or two forklifts, is a crane a better option? Will your project include longer-length IMPs being installed in a vertical orientation? If so, you may need special lifting equipment so as not to damage the panels. Whatever the details, crews need to be prepared to receive a project’s specific materials on site. A little advance planning will ultimately save you time and money by reducing labor and avoiding costly mistakes.

All buildings are not created equal. Just because a construction crew has had experience installing insulated metal panels on past jobs, doesn’t mean they can assume the process will be exactly the same every time. There will always be specific conditions and variables that need to be taken into consideration. Techniques used for vertical industrial panels will be different for horizontal architectural panels.

The vapor barrier (a key function of an IMP) is a great example of how a miscalculation can be problematic. Depending on the panel, the vapor barrier may be applied either at the factory or at the jobsite. If the project calls for a cold storage environment, the “warm” side of the vapor barrier will be on the exterior. Alternatively, a commercial or industrial application generally calls for the vapor seal to be on the opposite side of the panel. Confuse placement of the seal and you’re bound to run into problems down the road.

A crease or buckle on the face of a panel might seem like no big deal, but that couldn’t be further from the truth. In fact, framing alignment is one of the most critical aspects to ensure a proper fit-up of the construction as a whole. In terms of the panels themselves, not only will a framing misalignment not LOOK right but can also cause numerous efficiency and performance issues. Installing inexpensive shims can avoid panels needing to be replaced.

Additionally, make sure the first panel is plum and square, if you start right it is much easier to finish right.

Purlins must be level and square and all framing and bracing should be installed before installing panels. (The IMP manufacturer should specify the amount of tolerances allowed.) Also, take care with caulking and taping, foam-to-foam connections (in order to mitigate potential vapor leaks), seaming, and lap joints.

Attention to detail will avoid costly mistakes.

Being proactive may be the most important piece of advice construction crews need to hear.

For one, be sure to have a panel surplus on hand. You may be of the mindset that ordering extra panels is at worst a waste or at best, not worth the effort. This is a common judgement error that often leads to installation delays. If a crew has only ordered the exact number of panels needed for a job and there is any damage to the product, whether prior to delivery, on-site or during the installation, there a risk to the project schedule. Waiting on replacement panels can wreak havoc on schedules, especially with panels that may need special manufacturing due to custom components, finishes or colors. What do you do with extra panels you don’t need on the initial installation? Building owners can hold on to any surplus panels to be used as replacements, as needed, over the lifecycle of the building. A little preparation today can go a long way.

Other best practices include understanding the project’s site conditions and ensuring crews remain crews up to date on proper installation techniques—including staying current with training and certifications.

By taking this advice to heart, you can exponentially increase your ability to enjoy the many benefits of IMPs and be confident in your investment. For more information on MBCI’s insulated metal panels and proper installation guidelines, we encourage you to contact your local MBCI representative or visit our website.