Tag: durability

Looking Ahead: 2022 Trends at a Glance

Why Upgrade a Roof to Metal Panels?

Metal Panel Roof Restoration & Installation

Protecting Metal Panels from Rust

One of the many benefits of metal panels that contributes to their strengths is the fact that there are so many rust-resistant coating options with different levels of protection, making them a great option for virtually any environment or any budget. That said, though, missteps during storage, as well as during and after installation, can leave you with unwanted corrosion, i.e. rust. Factors such as improper storage, improper cutting, or other elements the metal might come in contact with can wreak havoc that are beyond the manufacturer’s control.

Regardless of the finish you have—painted, unpainted, high-end coatings or standard coatings—here are some simple installation and care instructions that can help further maintain the longevity of your metal panel product.

Preventing Rust When Materials Are Delivered

Proper material delivery/site storage is the first step to preventing rust. Be certain to check your panels while uncrating after storage on site for any early signs of corrosion, such as black discoloration or white rust/residue on them. This is a sure sign that that panel has been improperly stored and water has not been able to properly evacuate the panel bundles. Do not install any panel on which this has occurred, as the panel finish has most likely been compromised due to improper storage. If you go ahead and install it, that panel is going to continue to corrode and eventually lead to further rust/corrosion.

Make sure that you’re not trapping any sort of moisture in between the metal panels or restricting them from being able to drain when stored on site. Although the panel itself is corrosion-resistant, if you subject it to repeated and significant water being trapped in between the sheets by either not storing the material out of the mud and ground water, or if you’re not sloping the material bundles in such a manner that they can drain, then the result can yield “wet storage stains.” Therefore, if you want to prevent any sort of damage due to improper site storage, you must make sure that the panel is able to drain while stored and, if possible, tarp to resist heavy moisture concentrations such as snow and ice during inclement weather if necessary.

Preventing Rust During Installation

Next, let’s look at some installation no-no’s that WILL most definitely eventually lead to rust—and things to avoid. The first is the accumulation of drill shavings. Whether it’s a roof panel or a wall panel, when you’re installing the screws, even if you’re pre-drilling for the screws, you’re going to generate metal shavings. If those metal shavings are not removed and left to sit or cling to the sheeting those shavings will rust and will stain the roof or wall sheets. The shavings are uncoated/raw metal with no corrosion protection that can and will rust quickly. Eventually, the shavings may wash off or be blown off the roof or wall, but might not be until after they’ve stained the sheeting, thus leaving you with an issue to remedy and, since the “culprit” is gone, questioning if it’s just a stain or something more serious.

Remove the shavings as soon as you can to mitigate this issue. Additionally, if you’re going to do any field cutting, you need to do so via a shearing process utilizing the proper tools, such as electric nibblers, hand snips or electric shears. Any other type of cutting can cause the edge of the base material to become exposed and no longer protected by the Galvalume and painted coatings as they become disrupted. Using tools such as a “hot” saw, abrasive blades or even a reciprocating saw leads to a tearing motion rather than shearing motion, which will strip the metal of that protective coating; over time it can start to rust.

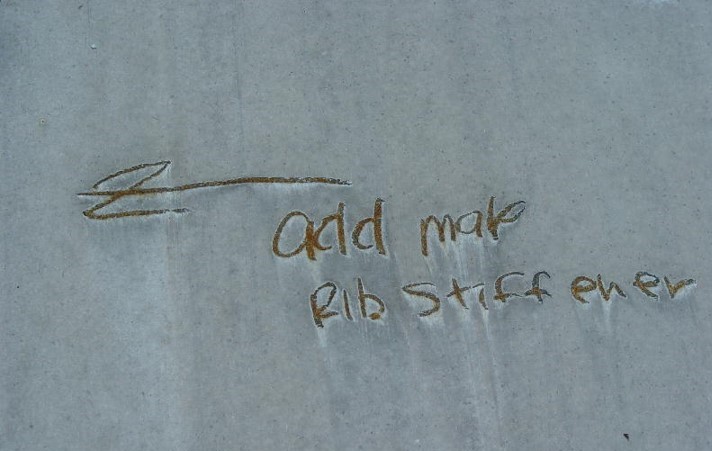

Graphite is another corrosive element that should be avoided as it is not a friend to Galvalume metals. Therefore, stay away from writing on your Galvalume material with pencils because over time the graphite will react, break down that protective layer, and lead to corrosion. If you do write on the panels with a pencil, make sure you clean it off. The best solution is to use permanent markers/Sharpies or dry erase markers.

Watch out for overspray from any adjacent wall coatings or finish systems like Stucco or similar masonry products, which can also damage panels if not removed promptly. And be certain not to rest the base of any metal panel in direct contact with material that is corrosive, such as concrete, or in such a manner that water can become trapped behind the panel and not able to drain. Industry recommendation is to maintain an eighth of an inch to a quarter-inch gap at the base of all your wall panels for not only expansion/contraction but for proper drainage and to prevent contact with dissimilar/corrosive materials.

Preventing Rust After Installation

Although Galvalume—whether bare or painted—is highly corrosive-resistant by nature, it too has its Kryptonite. Post-installation, the most important thing is to make sure you’re not adding something to the roof that’s going to react chemically/negatively with the Galvalume finish/coatings. For instance, many people don’t recognize that if they have mechanical units on a roof, the condensation that comes out of those mechanical units, when deposited directly onto a Galvalume panel over time, will lead to corrosion and rust. This condensate should either be filtered before exited onto the roof panel or drained via piping and not directly onto the sheeting.

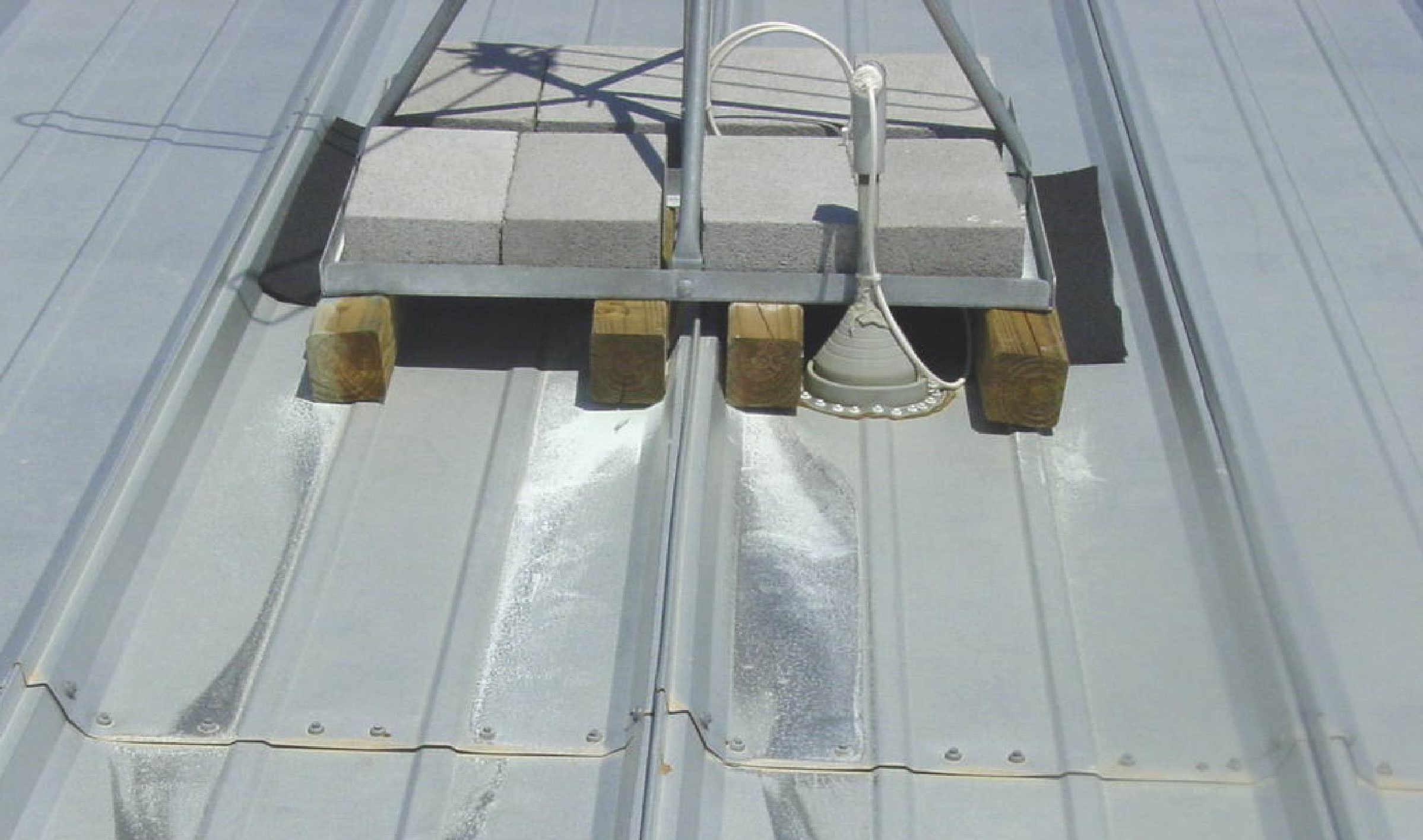

Contact with dissimilar metals, whether it be via incorrect type or method attachment from metal signage, solar panels and snow retention can be another major factor in post-installation corrosion. Panels must not come in contact with or be exposed to the runoff from the following metals: copper (lightning arrest systems, flashing, roof jacks, HVAC drainage); lead (roof jacks, pipe flashing); iron (pipes or soil); and, as previously noted, metal shavings.

Post-installation, panels must also not come in contact with or be exposed to the runoff from chemicals, such as acid from batteries and acid washing brick, and even pressure-treated lumber.

What To Do In Case of Rust

Let’s face it. Sometimes, despite all your efforts…someone didn’t get the memo and rust happens. Now what do you do? How can you safely can attempt to repair it or remove it without causing more damage?

First off, here’s what NOT to do. Heavy solvents that are meant to remove paint or stains can/will adversely affect the metal. If you witness a rust stain on the roof, don’t go up there with paint remover, acetone or any other toxic solvents and start scrubbing on it because you most likely could make matters worse. You might remove the stain along with the finish entirely, leading to bigger problems. (If you’re an end user, check your finish warranty and manufacturer maintenance documentation supplied to you by your builder/installer for guidance on cleaning and repairs.)

The key is to identify if the rust is just a stain /discoloration or it’s more systemic. Is the catalyst (ex.: a shaving) causing the rust still present? If it’s just a surface stain and the coating hasn’t been damaged, it might just be a matter of getting some mild detergents or something else to remedy the situation. Some good options are Formula 409 or Simple Green and Soft Scrub without bleach or something similar. and it may require a trial and error process to determine which is most effective based on the condition you’re trying to remedy. Products such as Rid O’ Rust or similar whose key ingredient is oxalic acid can be used diluted with water. With any of these products, test a small area first and wait to see results before proceeding to larger areas. And always be certain to fully rinse/flush areas of cleaning products to ensure no residues /films remain.

Always start light. Don’t break out any steel wool and/or metal grinders and start trying to get the rust off the panel that way. If it looks to be more than just a stain—perhaps you clean it and a few weeks later it comes back—that most likely means that the panel has actually been damaged and you’re not just going to get rid of the “stain” by cleaning it as it’ll return. It may require touchup paint or even a panel replacement. It depends on the severity of the damage. If this is the case, be certain to check with your installer, maintenance manual, and panel supplier for further instructions on how to address.

For more information on panel maintenance and warranties, see the MBCI website resource center.

Overhead Door Considerations for Metal Buildings

Selecting the right overhead door shouldn’t be an afterthought. As with metal panels, they should be a key consideration when planning and designing a commercial or industrial metal building. Functionality (i.e., size, operation and environmental concerns), security and quality are priority factors. In addition, location, climate and building codes should also be part of the overhead door solution decision. Selecting a door type and framing, in fact, can further depend on end use, strength/longevity needs, access and clearance/framing restrictions. Additionally, the type of door requested or required will impact the framing and support needed for installation.

With these criteria in mind, its of note that metal building manufacturers don’t always supply the overhead doors for a project. Therefore, ensuring compatibility and optimal performance requires viewing door options from top to bottom and side to side—figuratively and literally.

Overhead Door Types

Although MBCI primarily offers roll-up doors, these are not the only door options for metal buildings. The primary types of commercial doors for large metal building openings can include the following:

- Roll-Up Doors aka coiling/drum doors are typically a continuous corrugated sheet that nests into itself as its rolled around a cylindrical drum at the top of the door opening. This nesting allows them to take up far less overhead space as compared to doors that slide on tracks. Generally less expensive to purchase, roll-up doors also boast durability, maintenance and longevity benefits.

- Sectional Doors are typically smaller horizontal door leafs/ panels hinged together and mounted between two tracks on both sides of the door. This permits the sections to be lifted continuously either by transitioning horizontally back into the building above the door opening or vertically only above the opening, clearance permitting.

- Vertical or Horizontal Bi-Fold Doors are similar to sectional doors but have much larger panel sections, requiring fewer door panels. Manual operation is an option, however operation most often occurs via hydraulics with the support of door headers or jambs only and not via a full track system.

- Sliding Doors may be mounted via an external or internal horizontal track system at the top of a frame’s opening. Depending on door weight and size, sliding doors may rely on support from the top track system or lower guide rail mounts and wheels as well. Top-mount-only systems are prevalent on smaller commercial doors or in agricultural uses. Larger versions typically support industrial applications like airplane hangars and freight facilities.

- Walk Doors/ Man Doors are common to metal buildings of all sizes and types As a primary means of entry and exit. MBCI offers walk doors in varying sizes for commercial and industrial and agricultural building applications.

Planning Ahead: Coordination Is Key

Once you’ve selected the overhead door type best suited to your project, coordination with the building manufacturer is a must. Specifically, be certain that the building manufacturer knows the type and size of your doors before ordering your building materials. Here are some factors and situations you will want to account for:

- Door Opening Size: Allow ample space to ensure no obstructions when the door is in its maximum open position. Even partial obstructions may require building design adjustments to accommodate for larger openings.

- Door System Weight: The weight of the entire door system—including framing, sheeting, hardware and drive systems (if applicable)—can require certain design considerations.

- Clearances: When open, the horizontal and vertical panel clearances shouldn’t foul trims or building exterior cladding.

- Installation Clearances: Be sure to understand minimum interior building clear heights needed if installation of track systems are necessary. Or, if using roll-up doors, account for drum clearance and its proximity to roof framing, ceiling liners or roof insulation.

- Framing Materials: Be sure surfaces and flanges of framing materials are wide enough for proper attachment of door tracks. The same goes for mounting hardware and mechanical operators if so equipped and required.

- Bracing: If appropriate, evaluate any supplemental bracing necessary to keep the door opening square. Additionally, support for the door sheet in all positions should also be a consideration.

- Verify Manufacturer Requirements: Work with the door supplier and advise the building materials manufacturer if the door opening, framing and/support require minimum or maximum deflections/limits. This helps ensure proper operation when building framing deflects under various loadings. Failure to do so may prevent the door from opening or closing properly. This coordination is made easier when the same manufacturer providing the roof and wall materials also provides the overhead doors.

In Conclusion

Always ensure you’re getting high quality metal overhead door products and services that seamlessly integrate into new or existing metal building projects. Regardless of scope, MBCI can help you find the best overhead door solution suited to your needs and project specifications. Contact MBCI today!

Are Metal Panels An Ideal Low-Slope Roofing Material?

Many large, commercial, low-rise buildings often don’t benefit from steeply-sloped roofs the way residences and small commercial buildings might. This is because a steep roof slope would add unwanted height and unnecessary construction cost. Buildings like warehouses, retail stores, etc. are more appropriately built with low-slope roofing, commonly known as “flat roofs”. The National Roofing Contractors Association (NRCA) defines low-slope roofs as those with “a slope at or less than 3:12″. Anything steeper qualifies as a “high-slope roof”. With this in mind, let’s look at some key points to consider when designing and constructing a low-slope roof.

Low-Slope Roofing Materials

When it comes to selecting low-slope roofing products, there are generally three fundamental choices:

- Asphalt/ Bituminuous Products: The traditional commercial roofing norm for many years, the use of asphalt/bituminous products has dwindled as newer, more appealing options have emerged.

- Flexible Membrane Roofing: This roofing material can be made from a variety of types of plastic/polymer-based materials (commonly known as EPDM, TPO, PVC, etc.). Rolls of the chosen membrane are laid out on the roof structure and secured in place either with mechanical fasteners (screws with large washers) or with a continuous layer of adhesive.

- Metal Roofing: Sometimes overlooked, metal roofing is suitable for different roof slopes. Many metal roofs that use standing-seam systems are rated for use with a pitch as low as ½:12.

When considering which type of roofing material to use for a building project, there are a number of significant differences that illustrate why metal roofing is often the ideal choice.

Engineered For Superior Performance

Standing-seam metal roofing is made specifically for use on low-slope roofs as it meets a number of performance requirements:

- Water resistance: Precipitation doesn’t penetrate through metal or through the standing seams where the metal panels join together. This is why they can tolerate such low slopes, allowing the water to drain away slowly and predictably without leakage.

- Rigidity: The rigid nature of metal means that there is less opportunity for ponding (standing water). This is not always the case with asphalt/bituminous or membrane roofing systems.

- Drainage: Metal roofs carry water to the building’s edge toward gutters and downspouts that carry it away from the building. Other roofing systems rely on drainage piped inside the building. This takes up space and has the potential to leak water inside the building and cause damage.

- Wind Resistance: Standardized uplift testing shows that metal roofing performs as well or better in extreme weather than mechanically-fastened or fully-adhered membrane systems.

- Durability: The most cited advantage of metal roofing is its long-term strength and durability. Engineered design and use of high-quality coatings ensures a longer lifespan—50 years or more. In contrast, other roofing types typically feature lifespan ratings of 20 or 30 years.

- Puncture Resistance: Low-slope metal roofing is more puncture-resistant than asphalt/bituminous or membrane roofing. This makes it better able to tolerate foot traffic, hail and other puncture-inducing hazards.

- Construction/ Installation Ease: Metal roofing panels are custom-made to suit specific building sizes and end uses. This customization typically means it takes less time to place and install metal roofing in the field. Further, metal panels can tolerate a wide range of temperatures and weather conditions and still install and perform as intended. Low-slope roofs are also safer to walk on with less risk of slips, falls and other hazards.

Cost-Effectiveness

Using metal roofing on low-slope roofing systems can be cost effective in a number of ways:

- Fewer labor hours as a result of the ease of installation saves money during construction.

- Competitive material costs, particularly if the metal roofing is part of a total metal building package from a single manufacturer.

- Minimal maintenance requirements and aversion to rusting, mold growth and decay that save the building owner money over time.

This all adds up to a very favorable life-cycle cost.

The performance, cost-effectiveness and life-cycle benefits of metal roofing panels make them a viable option for low-slope roofing systems. Manufacturers like MBCI can help you select the right metal roofing products and provide information and resources to help ensure proper installation.

View examples of low-slope metal roofing projects and contact your local MBCI representative to start your project today.

Design and Performance Benefits of Insulated Metal Panels

In a prior post on insulated metal panels (IMPs) we reviewed some of the basic things everyone should know about this versatile and lightweight metal building component. In this posting, we will drill down a bit more on the benefits of incorporating IMPs into a new or retrofit construction project. Here are some of the top reasons they are so popularly used in both walls and roofs:

Energy Conserving, Space Saving Insulation

Foam plastic insulation is used between the metal skins of IMPs. Such insulation has been accepted for use by building codes for quite awhile provided it meets certain conditions. IMPs have been tested and shown to meet or exceed all code requirements for construction and for energy conservation too. Part of their appeal over other ways to insulate is that they can achieve high performance in a thinner wall or roof assembly than would be required with other types of insulation, such as fiberglass. IMPs are available in thicknesses that range from 2 to 6 inches and have corresponding R-values from R-14 to R-46 allowing design professionals to select the thickness that matches the energy performance level sought in a particular building. Other insulation types would require thicknesses of at least twice as much to approach the same R-values as IMPs. Further, the metal interior and exterior skins are the only finish material needed so the total panel thickness is very space efficient. Thinner IMPs in the walls and roofs can save space in the building or on the site all while achieving high energy performance.

Durability, Longevity, and Low Maintenance

The manufactured panels are rigid and quite strong. They have been tested for compression, tensile, and shear strength with impressive numbers that come about because of the combination of the rigid foam and steel properties. The surfaces are made from the same long-lasting galvanized and factory finished steel used in other metal wall and roof panels so their resistance to weather, abuse, and even harsh conditions has been proven, making them very easy to maintain. In locations where severe weather and storms are a concern, they can also be specified to meet requirements for heavy winds, hail, and similar concerns. Plus, since the skins of the IMPs are made of noncombustible steel, they provide an ignition barrier as part of an overall fire protection scheme for the building.

Cost Saving Construction

IMPs are an “all-in-one” product that takes the place of many other products and components used in traditional construction. Instead of requiring multiple trades and materials to be installed individually over some number of weeks, IMPs are installed by a metal building contractor and allow the walls and roof to be completely closed in with a single trade. The use of concealed fasteners in the side joint of the panels makes installation quick and easy. Unlike other construction systems, the inherent strength and resiliency of IMPs means that work doesn’t need to stop over weather concerns. All of this saves a considerable amount of labor costs and can also save a lot of time meaning buildings can be completed quicker and more economically. It could also mean that an owner is able to occupy and use the building sooner, thus reducing construction financing costs and allowing operations to begin more quickly.

Versatility for Use in Many Building Types

IMPs can be used in virtually any type of new construction and for many retrofit applications too. There is a range of modular panel sizes that can work successfully with different structural elements of the rest of the building. The finished profiles and colors can all be selected to match the design needs of the building with edges, corners, and trim details all based on simple, appealing aesthetics. There are even IMPs specially designed for cold storage or refrigerated space applications. These panels may be part of the building exterior or create an isolated space within a larger building. Either way, they are designed for the rigors of a high use installation.

With such a broad range of benefits and capabilities, you owe it to yourself to check them out for a building project that you may be involved in. The best place to start is by contacting your local MBCI representative, and by signing up for our newsletter to subscribe to our blog.

Doors of Steel: Metal Roll-Up Doors for Any Application

Metal roll-up doors are designed specifically to offer security and durability in a variety of applications. MBCI offers a series of roll-up doors to service the self-storage and commercial markets.

Here, we’ll provide some key product details to help guide you to the right product for your application.

Self-Storage Doors

Built to meet the specific and unique demands of a small structure, MBCI doors offer many standard features that make it a superior choice. These include a proprietary gear-driven tensioning bracket for safe and easy adjustments, a rust-resistant aluminum bottom bar to protect against the elements, and a standard stainless steel latch.

650 Series: The best choice for a low-maintenance, wind-certified self-storage roll-up door.

Transform your storage building’s exterior and protect your tenants’ assets with the 650 Series steel-curtain roll-up door. Wind-load tested in accordance with IBC, FBC, and TDI, the wind-certified 650 Series was engineered to protect and maintain building envelopes in extreme conditions without the heavy, weighted elements required in frequent commercial use. The 650 Series provides tenants and facility or building owners peace of mind with sturdy construction that requires little to no maintenance. Wind-rated up to 8’ 8” and approximately 90 mph, the 650 Series door is ideal in coastal areas that experience large wind gusts and hurricanes and comes with a 30-year film integrity warranty and up to 25-year chalk and fade warranty. Our 650 Series offers insulation for better energy efficiency and is perfect for climate-controlled storage. We also offer top and side draft stop kits to reduce drafts.

690 Series: The premium choice for mini-warehouse and self-storage buildings in areas susceptible to extreme winds.

The 690 Series steel-curtain roll-up door is designed to operate smoothly and perform well in severe weather. They won’t buckle, bow, become misaligned from the tracks, or separate from the door frame during strong storms and wind events. Featuring 16-gauge galvanized steel guides and a wind bar, the 690 Series is wind-rated up to 10’ and approximately 140 mph—ensuring they meet mini-warehouse wind-load requirements. Our metal roll-up doors are wind-load tested in accordance with IBC, FBC, and TDI, allowing facility managers to avoid higher up-front insurance costs and reduce maintenance costs and downtime in the event of a storm. For climate-controlled units, our 690 Series offers insulation to help improve energy efficiency along with our top and side draft kits.

Commercial Series

MBCI’s commercial-grade, steel curtain roll-up doors offer tremendous versatility, and unparalleled quality, are easy to install, and require minimal maintenance. With a variety of models, colors, and mounting options, it is our goal to provide the right door for any application and back it with the best warranty you can find. These commercial doors are available as light gauge and heavy gauge; some options are wind-certified.

Light-duty roll-up doors: Quality roll-up steel doors engineered to withstand frequent use and outperform others in the industry.

MBCI offers two steel roll-up doors ideal for light-duty commercial use in everything from warehouses and farms to recreational storage and auto body shops. Available with electric motors and multiple mounting options, the 1950 Series and 2000 Series are versatile and low maintenance.

1950 Series: Known for operating quietly and requiring less headroom, the 1950 Series door is suitable for a number of light-duty commercial and recreational uses.

2000 Series: The 2000 Series is the perfect door for light-duty applications that require frequent use.

Heavy-duty roll-up doors: The integrity, partnership, and quality behind the design and production of our heavy-duty commercial doors make them the most durable and reliable in the industry.

Perfect for high-traffic use, our heavy-duty, commercial-grade metal roll-up doors are suitable for warehouses, loading docks, terminals, and distribution centers. Our quality sets us apart; every MBCI commercial door features heavy-duty brackets made of a .187-thick angle, high-cycle spring life, and continuous-duty design. Wind-load tested in accordance with IBC, FBC, and TDI, our heavy-duty commercial-grade doors is wind-certified to meet stringent building codes in coastal regions, including Florida and Texas.

2500 Series: Our 2500 Series is a heavy-duty sheet door suitable for warehouse and freight buildings.

3100 Series: Wind-rated and available up to 16′ wide, the 3100 Series will last for years with little to no maintenance.

Wind-certified doors: Commercial metal roll-up doors from MBCI are wind certified to perform against high winds and meet building codes. Fueled by constant changes in local and national building codes, as well as increasing insurance costs, doors with validated wind certification can dramatically reduce maintenance and replacement costs and minimize downtime. MBCI’s wind-certified doors are wind load tested in accordance with BC, FBC, and TDI.

(Note: MBCI’s 2500 and 3100 Series are all wind-certified commercial door options.)

MBCI delivers the highest quality metal roll-up door products and services that seamlessly integrate into new or existing building projects. Regardless of the project scope or wind and weather variables, MBCI has the right solution when it comes to roll-up doors for self-storage or commercial needs. Download our capabilities brochure or contact your local MBCI representative to learn more about which product is right for you.

Standard Testing for Metal Roofing – Part 1: Structural Performance and Uplift Resistance

When selecting a metal roofing product, there is an expectation that it will perform as intended over the life of the building. But what assures building owners, code officials, or design professionals that a product will in fact perform as promised? This question often comes up in building product discussions and the accepted way to answer it is to subject the products to physical testing. The type of testing is usually very specific to the product based on protocols and procedures developed by independent agencies such as Underwriters Laboratories (UL), ASTM International, or others. Manufacturers typically submit their products to independent testing labs who follow these standard test procedures. Once testing has concluded, they report the results back to the manufacturer. These results then show whether the product meets stated performance criteria or not. If not, the manufacturer can re-design and re-test until it does and then make the final results available to the public.

For metal roofing, a series of relevant and important tests are typically performed. In this blog, we will look at two of them related to structural performance and wind uplift.

ASTM E1592

The structural integrity of metal roofing is crucial given the various natural forces that can be imposed on the materials. Effects from wind, snow, or other conditions can compromise its integrity. Accordingly, the ASTM Committee E06 on Performance of Buildings (including sub-committee E06.57 on Performance of Metal Roof Systems) has developed ASTM E1592 “Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference”. While the standard acknowledges the use of computation (i.e. calculations) to determine the basic structural capacity of most metal products, it also points out that some conditions are outside of the scope of computational analysis and hence need to be tested.

The standard describes a test method with “optional apparatus and procedures for use in evaluating the structural performance of a given (metal) system for a range of support spacings or for confirming the structural performance of a specific installation”. As such, it is very specific both to metal roofing and its installation. This test method uses imposed air pressure not to look at air leakage but simply to determine structural reactions. It consists of three steps:

1. Sealing the test specimen into or against one face of a test chamber

2. Supplying air to, or exhausting air from, the chamber at the rate required to maintain the test pressure difference across the specimen

3. Observing, measuring, and recording the deflection, deformations, and nature of any failures of principal or critical elements of the panel profile or members of the anchor system

The test needs to be performed with enough variation to produce a load deformation curve of the metal and account for typical edge restraint (fastening) representative of field conditions.

Manufacturers need to submit different products that are tested at least once at two different span lengths between supports. Standing seam roof panels are typically tested at a 5’-0” and 1’-0” span. Spans between the two tested spans can be interpolated. The result is a table of tested loading results that can be compared to code required or engineered design loading to then determine if the selected material and spacing are adequate for the project needs or if another product or spacing is needed.

UL 580

The ASTM E1592 test is focused on the structural integrity of metal panels. It also uses positive and negative air pressure in a static (i.e. non-moving) condition to determine performance. There is also a separate concern about how metal roofing will perform in a dynamic condition as would be expected in a windy condition where wind gusts can ebb and flow erratically. In that regard, a separate test developed jointly between Underwriters Laboratories (UL) and the American National Standards Institute (ANSI) looks at the ability of roofing to resist being blown off a building due to wind. Known as ANSI/UL 580 “Standard for Tests for Uplift Resistance of Roof Assemblies”, it has become the recognized means to identify and classify the suitability of roofing for different wind conditions – low to high.

This test is also specific in its scope and intent stating that it “evaluates the roof deck, its attachment to supports, and roof covering materials”. It also points out that it is not intended to test special roof conditions, main or secondary structural supports, or deterioration of roofing. The standard prescribes in considerable detail the type of test chamber that needs to be constructed and used for the testing which includes three sections: “a top section to create a uniform vacuum, a center section in which the roof assembly (i.e. deck, attachment, and roofing) is constructed, and a bottom section to create uniform positive pressure”. The test procedure is then based on placing the roof assembly into the test chamber and subjecting it to a prescribed sequence of 5 phases of oscillating positive and negative pressure cycles (simulating dynamic wind conditions) over 80 minutes of total testing.

There are four wind uplift classifications obtainable for a tested assembly based on the test assembly retaining its attachment, integrity and without any permanent damage. These include Class 15, Class 30, Class 60, and Class 90. Each class has its own requirements for test pressures with increasing pressure as the class number increases. Higher class numbers indicate increasing levels of wind uplift resistance. Note, that to obtain a Class 60 rating, the tested assembly must pass the Class 30 test then be immediately subjected to the Class 60 test sequence. Similarly, to obtain a Class 90 rating, the tested assembly must first pass both the Class 30 and 60 tests. Metal roofing manufacturers who want their roofing products tested and classified under UL 580 must pair them with standard roof deck and fastening materials. Hence most have many different tests performed and results reported accordingly.

When reviewing metal roofing options, it is comforting to know that most manufacturers have tested their products and designed them to meet or exceed minimum requirements. To find out more about tested results of products you may be considering, contact your local MBCI representative or see the MBCI website and select the “testing” tab under a selected product.